Types of Pallet Racking

Pallet Racking Style Guide

There are many different types of pallet racking

There are many different types of pallet racking. We’ve compiled an easy to follow style guide so that you know what to expect before you buy. Read through our guide to learn about the 8 most popular types of pallet rack.

Be aware that not all styles are compatible with one another. Refer to this guide to ensure that you choose compatible pallet racking when making your final decision.

Getting Started with picking a type of pallet racking

To identify the type of pallet rack, look at the connection point between the beams or uprights. The following guide and included images will show the various types of connectors. These various connectors are normally associated with a particular manufacturer. Some styles use a hook & slot connection, while others use pin & slot connection, or brackets or fasteners. Although some styles may look very similar, you’ll be able to tell the difference by looking at defining features like a lock mechanism. The colors of uprights and beams often vary by manufacturer with specific color combinations. You’ll know the differences by inspecting the breakdown of the styles listed below.

“The staff at Conesco Storage Systems is responsive, prompt, professional and courteous. From Bill, who took my first call to Scott who came to my place of business to spec the job, excellent service! I look forward to continued business with Conesco.”

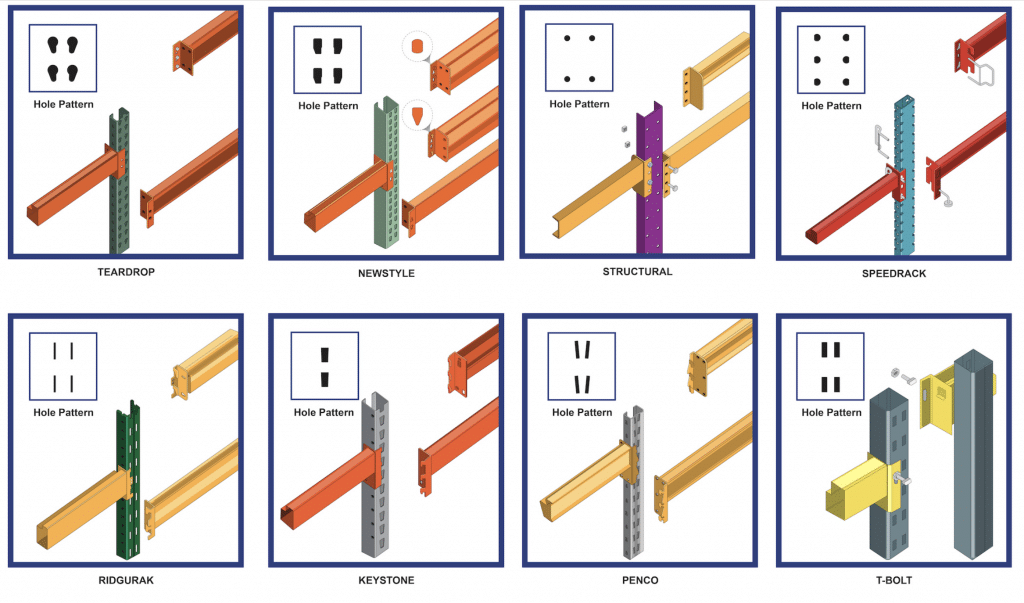

1. Teardrop Style

Teardrop, also known as Interlake Old-Style, is the most popular type of pallet racking in the country. This style can be identified by looking at the pin connector on the load beam or the slot connector on the upright. The slots on the upright look like an inverted teardrop, making this style very easy to identify on uprights. The load beams have circular pins that fit in the upper part of the teardrop, dropping down and smoothly locking into the upright. Teardrop load beam pins are spaced 2” or 4” apart center-to-center. The style of racking can be recognized by its orange load beams and blue uprights. Interlake Mecalux is the largest manufacturer of Teardrop style racking. Conesco has new & used options available.

“Working with Conesco was great. He asked the right questions, understood what we needed and our Denver Facility went in under budget. Good guys and good prices.”

2. Sammons Style

The majority of Sammons style racking can be found on the West Coast, where the manufacturers were once located. This type of racking is often mistaken for the Teardrop style because of the similar hole pattern. However, the Sammons style hole pattern sits on 4” centers vertically. The teardrop shape is only compatible with Sammons mushroom-shaped connector pins. Sammons style racking is most commonly found with grey load beams and grey uprights. The largest manufacturer of Sammons style racking is Hannibal Industries.

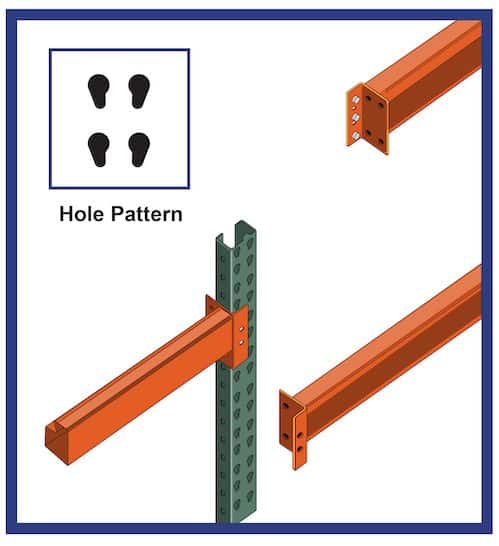

3. Newstyle

You can find Newstyle, also known as Interlake New-Style, in warehouses all over the United States. This is a good type of pallet racking if you are looking for used pallet racking because Newstyle is compatible with Teardrop style racking. You can connect Newstyle load beams with Teardrop (Interlake Old-Style) uprights. Newstyle uprights can be identified by the slot connector on the upright. It has a rectangular shape with a slight inward slant towards the bottom. The Newstyle beams are also offered in a shaved pin style or tooth pin style. The pins are spaced 2” or 4” apart center-to-center. Newstyle racking is most commonly found with Orange load beams and Green uprights.

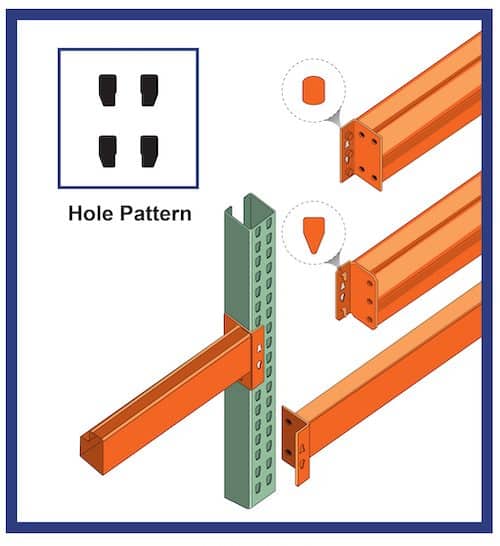

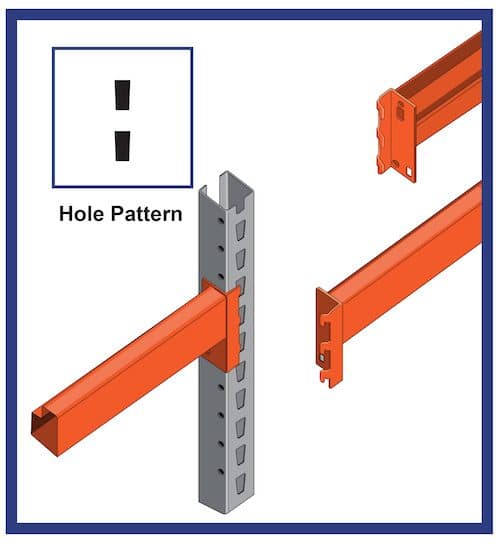

4. Structural Style

Structural racking is an extremely durable and versatile type of pallet racking while having a simple construction and connector type. Structural style uprights and beams are constructed from hot rolled steel and are highly impact resistant and designed for greater weight-bearing capacity. Instead of utilizing hooks or pins to connect with uprights, Structural load beams utilize bolts which bolt directly into the uprights. Structural uprights come in single column or closed post column styles offering additional reinforcement for greater load capacities. The uprights feature basic circular holes spaced 4” apart center-to-center. Beams are fastened to the uprights with ½” bolts.

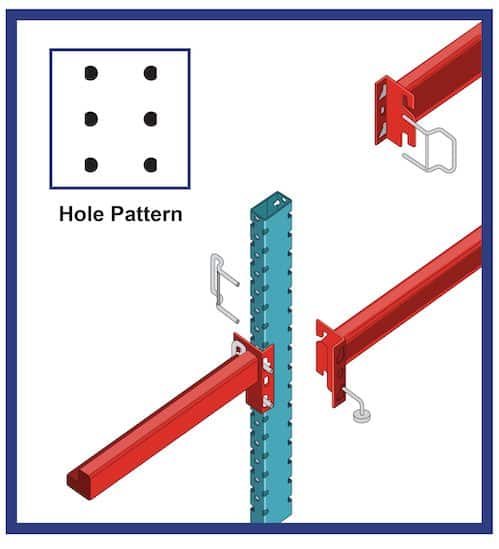

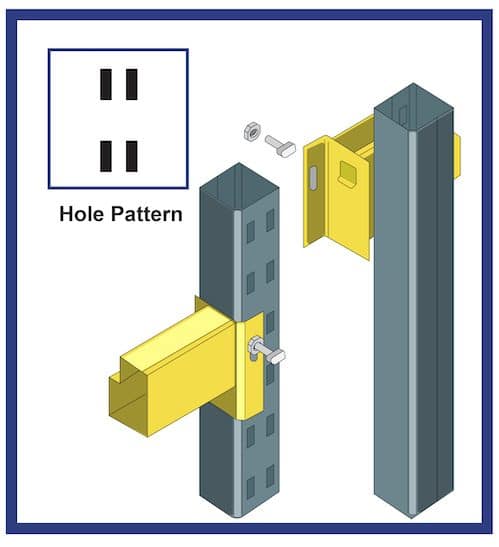

5. Speedrack Style

Speedrack is known for its unusual hole pattern and beams that have no pins or hooks. The beams attach to the uprights through a U-shaped bracket connection. The hole pattern on the upright consists of ½” circular holes located directly on both edges of the face of the column and are spaced vertically 4” apart center-to-center. U-shaped brackets pass through these holes from one side to another and are secured with a J-hook to lock in the load beam to the upright.

6. Ridg-U-Rak Style

Ridg-U-Rak style racking has rectangular slots located on the uprights where the hooks connect. The slots are spaced vertically 4” apart center-to-center. Ridg-U-Rak uprights have an outward bend on each internal side of the column. The beams have hooked flanges, resting against the ridge of the upright. The beams are more thinner than other beam styles and feature hooked connections. Ridg-U-Rak also use a spring component with two pins as a lock that is installed inside the upright column.

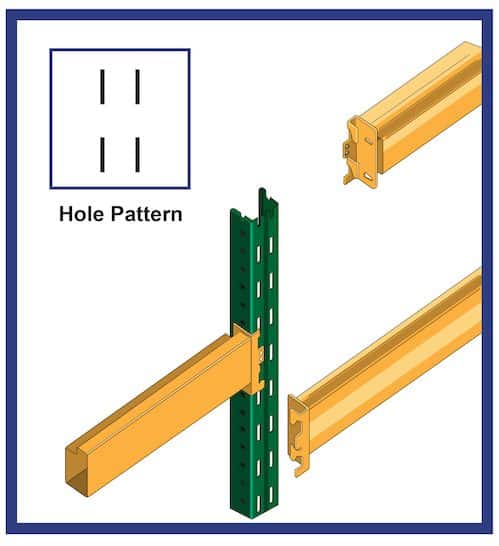

7. Keystone Style (also known as Republic)

Keystone (aka Republic) racking utilize a hook & slot connection. Keystone style has a trapezoidal hole pattern on the upright. These slots are located on the center of the face of the column and are spaced vertically 3” apart center-to-center. The beams are roll formed and feature hooks that slide into the slots on the uprights. The beams are secured to the uprights with J-hooks or a removable steel clip.

“I have worked with Conesco for over 8 years, they are leaders in the Racking Industry, exceptional customer service and great in every aspect to work with. I refer them to all my customers with racking needs.”

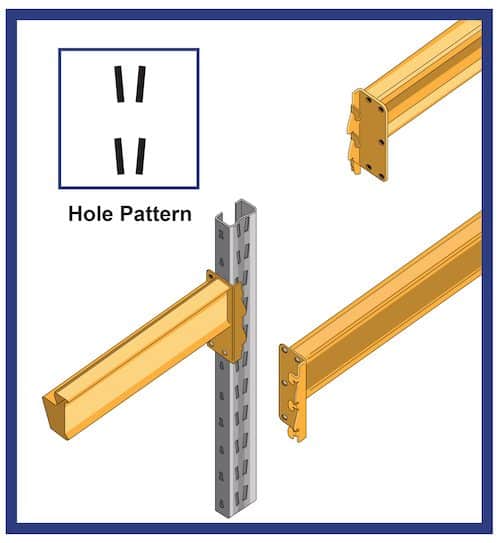

8. Penco Style

Penco style racking also use a hook & slot connection. The uprights are identified by the side by side slanted narrow slots and beams with slanted hooks that fit snuggly into the slots on the face of the uprights. The beams also have a tapered look to them when you look at the cross section. These beams are locked into place with a sliding lock incorporated into the beam.

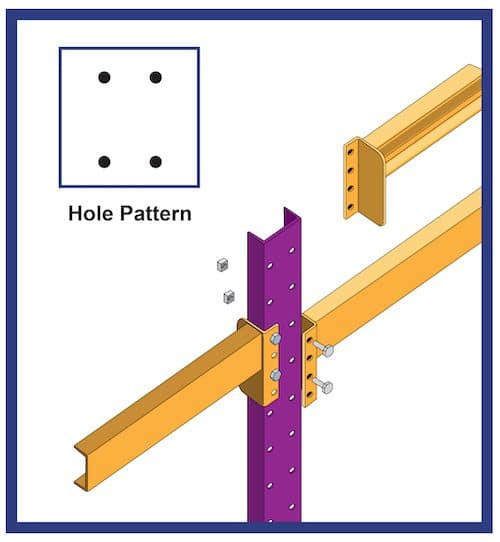

9. T-Bolt Style

T-Bolt style racking is another common variety of racking that can be identified by the rectangular slots on the columns and the similar slots on the load beams. T-Bolt beams are attached to the uprights with large bolts that have to be tightened properly. The standard T-Bolt connection has a bolt on each end which holds the beam in place. T-Bolt load beam connections are available with 6″ to 12″ connection clips for high seismic design areas. T-Bolt racking most commonly has Blue uprights and Yellow load beams.

Types of pallet racking FAQs

CONESCO serves the entire United States from multiple locations.

We get that question all the time! It depends on many factors such as:

- will the warehouse be shut down or,

- will it still be operating?

- How much material is there?

- Are the uprights bolted down to the ground?

Best practice is to give yourself multiple months of time in planning so that way you provide a buffer for your project to finish according to a timeline. Getting a full count of the materials and good pictures is a great way to start the process of evaluating the decommission of your warehouse.

It might be quicker than you think! The first step is to give us a call or have us call you. Once we have a good understanding of your unique situation, we typically provide a quote within 5 days and will schedule a time with you to have one of our team members come visit your site.

Yes! There are a few things that will need to happen in order to ensure everyone’s safety and some other items need communicated like an agreed upon timeline. It’s true, an operating warehouse will sometimes slow down a teardown project. But, we understand it’s necessary to avoid disruption of your business during the warehouse shelving and equipment removal process.

We are looking to purchase large quantities of pallet racking and most other warehouse equipment.

Our specialty is in used pallet racks (uprights, beams, wiredecks, pallet supports), pallet rack accessories (like guide/ guard rail, netting), conveyor systems, mezzanines, and pick modules. If your warehouse also includes different material like

- balers

- shrink wraps

- or lifts,

then we can buy/ remove those as well.

Sometimes material is in bad shape or is a very uncommon size or outdated brand. In some of these cases we do not purchase the materials, however we still can provide you with our teardown services to remove the materials from your warehouse. We encourage everyone to reach out so we can better understand what is in your warehouse and what your intentions are. Once we have a good understanding, we are happy to provide you with our recommendations, even if that means not using us.

Absolutely! Removing used warehouse equipment is a messy job. All debris will be properly disposed of and the floors swept.

No. Removing floor anchors does create holes but we take responsibility for grinding them down to be flush with the cement or fill them with cement epoxy.