The Ultimate Guide to Structural Engineering and CAD Drawing Services for Optimal Warehouse Design

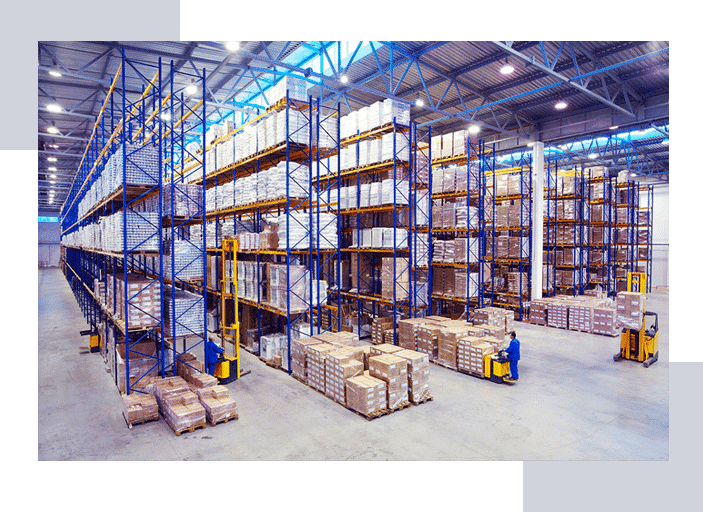

Whether you are building a new warehouse, modernizing your current facility, or looking for a more efficient layout, structural engineering design services for warehouse layout are key to creating a safe, efficient, and compliant solution.

The Importance of Structural Design for Warehouses

Proper structural design is mission-critical for ensuring the safety of your warehouse workers and complying with warehouse building regulations. Warehouse building codes and requirements can differ greatly depending on your location but may include such items as:

- Egress and exit points

- Aisle width

- Load-bearing capacity

- Fire resistance

- Structural stability

- Seismic stability

Safety

Warehouses are inherently dangerous places. Heavy loads, constant motion, and machinery create potential conflicts. In an industry with turnover rates as high as 300% in many operations, a constant flow of new employees also contributes to safety concerns.

More than ten thousand on-the-job accidents occur every year in warehouses across the country. 16 people died in warehouses in 2023 in the U.S. Structural engineering design services for warehouse layout emphasize safety first.

Risk Mitigation

Structural integrity in warehouse design services can help mitigate substantial risk. For example, failing to meet standards can endanger your employees and expose you to fines, penalties, and lawsuits. Besides the human cost, accidents lead to downtime and significant expense. According to the National Safety Council (NSC), work injuries cost $167 billion annually, including:

- Wage and productivity losses

- Medical expenses

- Administrative expense

The cost per worker adds up to $1,080—the value of the goods or services a worker must produce just to offset the cost of a work injury. If an injury requires medical attention, the costs rise to an average of $42,000. In the case of a fatal accident, the average cost is $1.34 million.

Besides these hard numbers, the NSC estimates that time lost due to work-related injuries adds up to 70 million workdays.

It’s important to be aware of Occupational Safety and Health Administration (OSHA) fines and penalties for failing to provide a safe environment for your employees. OSHA increased the fines in 2024 for violations to $16,131 per violation. Failing to remedy violations by OSHA’s abatement dates can tack on another $16,131 per day. Willful or repeated violations can increase fines tenfold to $161,323 per violation.

Clearly, you need a structural design that creates an optimal layout for safety. Warehouse design services, including CAD drawing services, can build the foundation you need for a safe environment that also creates efficient throughput.

Space Utilization

According to CBRE, the cost of warehouse construction has increased significantly over the past few years, now averaging nearly $74 per square foot. Despite increases in vacancy rates, Colliers estimates the average cost for renting warehouse space is $9.74 per square foot in 2024, a 20% year-to-year increase.

Whether you build or rent, space utilization is crucial to minimize your costs. Efficient warehouse design services can create the optimal layout for your warehouse to maximize storage capacity and create an efficient flow for material handling.

Design engineers can work with your space to create custom solutions. For example, a modern high-bay warehouse may include columns and long-span structural systems that provide uninterrupted storage aisles and optimal pallet rack configurations.

Operational Efficiency

CAD drawing services can enhance operational efficiency. By reducing potential conflict points, streamlining material flow, and creating efficient equipment layouts, you can improve productivity and throughput. For example, you can improve safety and reduce travel time, which represents nearly half of labor costs in retail warehouses and fulfillment centers. With labor costs continuing to increase and continued concerns about warehouse staffing, an efficient design that reduces labor costs is essential.

What Is Included in Structural Design for Warehouse Layouts?

Depending on your requirements, what is included in structural design for warehouse layouts can vary greatly. Warehouse design services will work with your space, considering any layout constraints, workflow concerns, automation, and material storage.

CAD drawing services can take all of these factors into account to create a safe environment with:

- Efficient pathways and traffic flow to reduce potential human-machine conflicts, such as forklift accidents

- Elimination of blind spots and improved visibility in warehouse layouts

- Proper loading and unloading access to maximize safe operations

- Height and weight load estimates based on material storage

- Emergency exit routes and fire protection systems

Layouts also need to accommodate location-specific requirements. Much of the country resides in seismic zones. Designs need to ensure they can withstand seismic activity. In some cases, this requires additional reinforcements or special seismic racking.

There may be specific requirements for permitting and approval depending on your location. For example, there are typically height limits for installing racks without a permit. Structural integrity reports are typically required for high-pile storage to confirm their ability to handle the weight load efficiently.

With warehouse design services from Conesco Storage Systems, you get an efficient warehouse layout to optimize workflow and prioritize safety. CAD drawing services provide the engineer-approved drawings you need to accelerate the permitting process as well. In addition, you get the expertise of one of the nation’s largest warehouse equipment distributors with expert recommendations for equipment and automation systems to streamline operations.

Employing Different Warehouse Design Strategies

There are three common warehouse layouts and there are pros and cons to each. Your warehouse designer can help you find the best fit for you.

U-shaped Warehouse Designs

U-shaped warehouses are the most popular. Inventory is arranged in a U-shaped semicircle with the middle being used for storage. Shipping and receiving are at the ends of the U.

| U-SHAPED WAREHOUSES | |

| PROS | CONS |

| Efficient use of space to maximize storage | Potential congestion in central areas |

| Streamlined flow and clear pathways | May be challenging to expand warehouse layouts |

| Improved visibility for overseeing operations | May present accessibility issues for forklifts |

| Can accommodate various types of inventory and configurations. | Requires a large footprint compared to other solutions |

I-shaped Warehouse Designs

I-shaped warehouses are often preferred by businesses that operate large facilities with high volumes. Receiving is at one end, with dynamic storage in the middle, bracketed by more static storage on the sides. Staging, fulfillment, and shipping are at the other end of the I.

| I-SHAPED WAREHOUSES | |

| PROS | CONS |

| Linear flow for improved efficiency | Potential congestion in dynamic storage areas |

| Allows for different zones for types of storage | Less visibility across the entire warehouse layout |

| Easier to expand vertically or horizontally | Requires more careful planning for workflow |

| Provides better organization and categorization of inventory and materials | May require significant structural modifications to change the layout |

L-shaped Warehouse Designs

L-shaped warehouses are configured when receiving is on one side of the building and picking or shipping is located on an adjacent side at a 90-degree angle. The rest of the space is used for storage and staging.

| L-SHAPED WAREHOUSES | |

| PROS | CONS |

| Separates receiving and shipping to prevent congestion | Requires considerable space to implement |

| Adaptable to meet various site and operational challenges | May require separate equipment for loading/unloading |

| Improved traffic flow | Increased travel distances for different zones |

The Role of Structural Engineer in Warehouse Design

What does a structural design engineer do for warehouse layout? Structural engineers ensure your layout complies with applicable laws and regulations, and they validate equipment for structural integrity. By incorporating the right type of equipment for the job in an efficient layout, you get an optimized floor plan for efficient workflow.

A structural design engineer will provide the CAD drawing services to create a blueprint for your construction or layout. They will work closely with your warehouse operators to understand their operational requirements and constraints. Considerations include factors such as:

- Types and quantities of materials in the warehouse

- Frequency of access and types of access needed

- Material handling equipment requirements

- Potential change or expansion plans in the future

Design engineers will also provide a plan to optimize visibility and workflow. For example:

- Designing bay sizes and column spacing to maximize storage density

- Ensuring adequate aisle widths and clearance for material handling

- Minimizing obstructions for better visibility and sightlines

- Incorporating a long-span structural system to create more open (uninterrupted) spaces

Depending on your needs, this can include additional strategies for improving workflow, such as:

- Material flow analysis to minimize bottlenecks and optimize the movement of goods

- Integration of warehouse automation, such as conveyors or automated storage and retrieval systems (AS/RS) solutions

- Mezzanines to improve vertical storage

- Flexible design to accommodate changes to workflow over time

Conesco Storage Systems has expert warehouse designers with years of experience to help you create the most efficient space.

Conesco Storage Systems Warehouse Design Services

Conesco Storage Systems comprises industry experts with more than 250 years of combined warehouse planning and material handling experience. Whether you are starting from scratch, updating your configuration, or modernizing your facility, the Conesco team can help you plan the most efficient and safe design for your new and used material handling equipment.

Our team focuses on three core principles: safety, efficiency, and cost reduction. You must prioritize safety to avoid accidents. Efficiency is key to productivity and improving output. At the same time, you want the most cost-efficient solution that meets your needs. Warehouse design services from Conesco Storage Systems achieve those goals. Conesco also incorporates sustainable warehouse principles to help you minimize your carbon footprint at each step.

Conesco’s warehouse design service team will take the time to discuss your unique needs and deliver efficient solutions that work with your budget—considering the pros and cons of different solutions, layouts, equipment, and automation.

Conesco Storage Systems offers custom warehouse design services, including:

- Plant and warehouse layouts

- Conceptual development

- CAD drawing services

- Progressive work

- Automated storage and retrieval systems

- New installations or system upgrades

Conesco helps you create the perfect warehouse layouts. Besides warehouse design, we can also set you up with new or used warehouse equipment from top manufacturers and provide installation and labor for new construction, renovation, expansion, and retrofits. Our designers work closely with your internal team and our team of warehouse experts who have high purchasing power. Because of the large volume of warehouse designs and equipment installs the Conesco team does, this creates greater buying power with top manufacturers to negotiate better pricing.

As one of the nation’s leading warehouse liquidators, Conesco Storage Systems also has access to a large inventory of high-quality used warehouse equipment to complement your layout.

When you work with Conesco for your warehouse design services and CAD drawing services, you get the following:

- A safer environment for your employees

- Optimized utilization of your floor space

- A more organized approach to storage and workflow

- Increased efficiency and better throughput

You can trust the team at Conesco Storage Systems to design the optimal warehouse layout for peak performance.

Frequently Asked Questions—FAQs

What is identified as structural design for warehouse layouts?

Structural engineering design services for warehouse layout plan the physical infrastructure to ensure safety, compliance, and efficiency. This includes making sure layouts have the proper aisle widths, traffic flow, equipment placement, fire resistance, and load-bearing capacity.

How much does it cost to get a CAD design for a warehouse?

The cost for CAD drawing services can vary widely depending on the warehouse size, constraints, complexity, and level of detail provided. You can consult the warehouse design experts at Conesco Storage System for a personalized quote.

What is the best warehouse layout?

There is no one-size-fits-all layout when it comes to warehouses. The best design will take into account your unique situation. However, the best warehouse layouts will include efficient storage, optimized space utilization, safe operating conditions, and technology to fit your needs.

How do CAD drawing services help with permitting?

CAD drawing services provide engineer-approved drawings that serve as blueprints for warehouse construction or layouts. They provide the documentation that is typically required for permitting and approval to demonstrate compliance with building codes and regulations.

Request a consult with Conesco’s expert warehouse design services team online or by calling Conesco Storage Systems today at (303) 690-9591.