Beyond Pricing: Find a Materials Handling Equipment Partner Who Understands Warehouse Needs

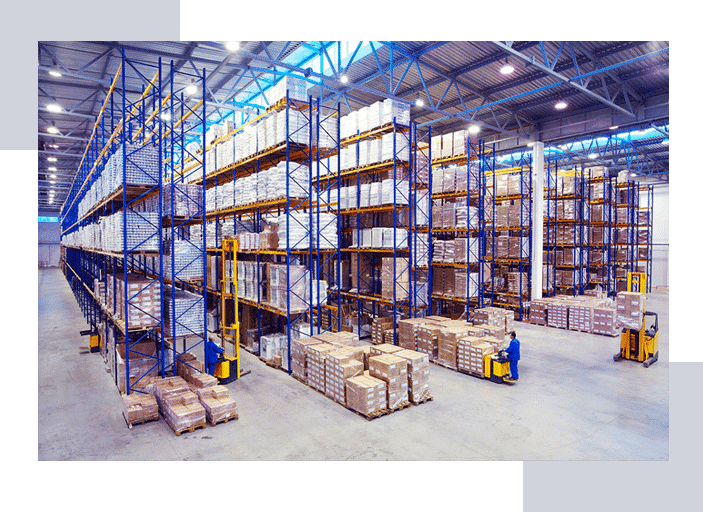

Your warehouse layout and equipment make a significant difference when it comes to flow and throughput. When you are looking to buy material handler equipment, it’s about more than just equipment pricing. Designing and operating an efficient warehouse requires a partner who understands modern warehouse needs and has deep experience in creating productive environments.

What Is Material Handling Equipment?

Material handling equipment includes all of the equipment you use to move, store, control, and process your materials and inventory. Over the past few years, there have been significant improvements in material handler equipment, creating opportunities for warehouse operators to streamline operations and cut costs. This has been particularly important in light of today’s challenging (and increasingly expensive) labor market and volatile economic conditions. With labor costs rising more than 7% over the past year, finding efficiencies and automating processes is key to cost control.

Warehouse Needs Are Evolving

The growth of eCommerce has led to increasing fulfillment challenges. Whether you are in the eCommerce business or not, you have probably seen the increased demand from customers for faster order processing and shipping. This demands increased efficiency.

An increased emphasis on automation to assure consistency and speed is crucial in meeting these needs. At the same time, some warehouse operators are looking for ways to downsize their workforce or facility infrastructure to reduce costs. Automation helps in both cases.

So, when you are looking to create these efficiencies, you need more than just a material handling equipment seller. You need an experienced partner who understands warehouse operations.

How to Find the Right Material Handler Equipment Partner

Here are a few areas to evaluate to find the right material handling equipment partner for your warehouse.

Consultative Approach

The right partner will take a consultative approach, taking the time to understand your current warehouse operations and challenges. This includes assessing your inventory systems, order profiles, fulfillment workflows, peak volumes, and bottlenecks. With this understanding, they can then recommend equipment and layout optimizations tailored to your needs.

Warehouse Design Experience

Partner with a company that has expertise in warehouse design and optimization. They should evaluate factors such as space constraints, inventory slots, order-picking strategies, storage methods, safety protocols, and automation integration. Experienced partners can develop smart facility layouts and material flows to reduce travel time and optimize productivity.

Workflow Assessments

Before installing any equipment, your partner should complete an in-depth workflow assessment. This evaluation can identify bottlenecks, redundancy, excess motion, and opportunities to streamline. Understanding workflow pain points ensures the right equipment gets placed in the right facility areas to address fulfillment process constraints.

Knowledge of Technology

The materials handling industry continually releases new equipment technology like smart conveyors, picking robots, autonomous mobile robots, and more. An ideal partner stays on top of these developments and can explain your options clearly.

They can then help select the best technologies for your operations today as well as build in flexibility for future technology adoption.

Automation Integration

Many warehouses are automating elements like inventory tracking, order routing, equipment controls, and metrics analysis. When adding automated equipment, make sure your partner has competence with relevant hardware and software integration. This experience ensures cohesive integration of automated controls and optimization of data tracking.

Customization

While many equipment options are turnkey, custom capabilities can optimize for unique layouts and workflows. Determine if your partner offers customized conveyors, platforms, controls, or modified picking stations tailored to your facility. These custom touches ensure optimized flow.

Choosing the Right Material Handling Equipment Partner

The right warehouse equipment can transform your operations, but mistakes are costly. It is crucial you find a warehouse equipment partner and not just an equipment vendor. Besides selling you equipment, a partner like Conesco will take the time to determine the extent of your needs and create a material handler equipment plan to maximize your operations.

Conesco has more than 30 years of experience in the material handler equipment business and is an industry leader in warehouse operations. Conseco can help you find cost-saving opportunities, including pre-owned material handling equipment. High-quality used material handling equipment like pallet racking, pick modules, conveyors, mezzanines, cantilever racking, carton flow, drive-in, and push back can reduce costs while providing significant operational improvements.

Call the Conesco team at (303) 690-9591 or request a consultation online to discuss your warehouse equipment needs.