Investing in Industrial Material Handling Equipment: What to Consider

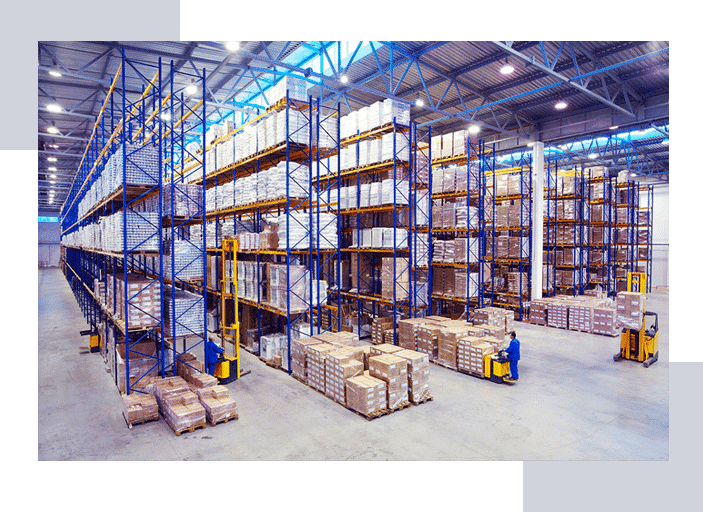

Industrial material handling equipment is at the heart of warehouse operations, efficiently and safely moving goods and inventory. Choosing the right equipment for your facility can improve workflow, reduce costs, and increase safety.

When deciding what to buy, however, you have a wide variety of options. The experts at Conesco Storage Systems can help you find the right industrial material handling equipment.

Why Choosing the Right Material Handling Equipment Matters

Whether you need pallet racks or automated material handling equipment, you want top-quality equipment that fits your specific operational needs and can handle the types of material you work with. The right choice provides significant benefits:

- Improved workflow: When you use material handling equipment designed for specific tasks, you can streamline your operations and eliminate bottlenecks. For example, conveyor systems can automate material transport and assembly processes, reducing manual work and errors and increasing productivity.

- Enhanced safety: Safety should always be at the top of your priority list. The right equipment minimizes the risk of injuries and accidents in your warehouse, protecting your workers and avoiding costly downtime. For instance, anti-collision systems and sensors can prevent collisions between forklifts and other objects or people, while ergonomic handles and controls can reduce strain and fatigue for operators.

- Resource optimization: With the right design, you can make the most of your available resources and save money in the long run. For example, shelving systems and automated storage and retrieval systems (AS/RS) can maximize your storage capacity and density, while advanced picking solutions can improve your order accuracy and speed.

How to Choose the Best Material Handling Equipment for Your Operation

Buying the wrong new or used equipment can lead to significant-and expensive-problems. Here are some of the key areas you should consider to make the right investment.

Warehouse Space

Measure aisle widths, vertical clearances, and storage configurations to determine space and maneuverability prerequisites for equipment. This informs the selection of machinery sized and designed to optimize area utilization and material flow. Keep in mind any future expansion or reconfiguration plans.

Material Handling Needs

Analyze material types, volumes, weights, and handling needs. Whether dealing with bulk goods, delicate items, or specialized products, identify requirements to match equipment specifications to applications. You should also consider the variability and complexity of your materials, such as density, dimensions, and packaging, and choose industrial material handling equipment that can accommodate different scenarios.

Load Capacity

You should evaluate the maximum loads that your equipment will have to handle, including the frequency and duration of your loading and unloading operations. Equipment that exceeds weight limits can compromise safety, performance, and longevity.

Process Complexity

Simpler tasks may only require basic equipment, but complex operations involve advanced machinery with specialized features. The number of handling stages, volume, and ancillary system integration may indicate a need for more automated material handling equipment.

Ease of Use

Prioritize simplicity and ease of use. Intuitive, user-friendly designs minimize training needs, enhancing workforce confidence and satisfaction. Machinery that is easy to operate also improves safety and efficiency.

Buying Used or New Material Handling Equipment

You have options when it comes to buying new or used equipment. Here are some of the pros and cons of each.

New Material Handling Equipment-Pros and Cons

- Pros: Latest technology, warranty coverage, reliability and longevity, more customization options

- Cons: Large upfront capital outlay, longer lead times, equipment depreciating quickly

Used Material Handling Equipment-Pros and Cons

- Pros: Significant cost savings—often 30% to 50% of original equipment, immediate availability, multiple options

- Cons: There may be hidden problems, shorter lifespan, outdated technology, and replacement parts may be limited.

Making the Right Decision

Choosing the right material handling equipment for your warehouse should start by working with trusted experts in the material handling and storage industry. Conesco Storage Systems has more than 30 years of experience equipping warehouses, distribution centers, and fulfillment centers with both new and used equipment.

As one of the nation’s top warehouse liquidators, Conesco has access to a wide variety of used equipment. You will get an honest appraisal, so you know the quality and durability of what you are buying, along with market-leading pricing. The Conesco team can help you choose new equipment from the industry’s leading manufacturers.

When you work with Conesco Storage Systems, you get a professional review to help you find the perfect equipment to meet your needs and a customized proposal for your consideration.

Before investing in industrial material handling equipment, call the Conesco team at (303) 690-9591 or request a consultation online.