How to Plan a Warehouse Relocation: Staffing

Materials Handling Staffing Solutions

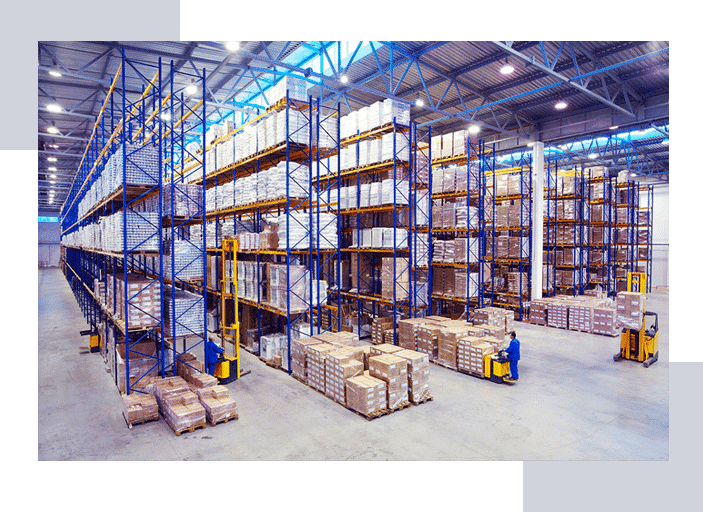

Relocating to a new warehouse is a logistical challenge for companies of any size. Moving to a new facility while keeping current operations running requires thorough planning to avoid disruption and make for a smooth transition.

The team at Conesco Storage Systems are experts at material handling and warehouse relocation services. We can help you plan the perfect move, provide the staffing you need to get the job done efficiently, and help restore your current facility to a broom-clean finish.

A Smooth Warehouse Relocation

Assuming you have already decided where to move, here are the key things you need to address when planning your warehouse relocation.

Layout

Warehouse relocation offers an opportunity to rethink your space for better utilization and workflow. Before simply replicating your layout in a new facility, you will want to examine whether there are efficiency gains from a different layout.

You may be comfortable with the way things are now, but there is a variety of layouts and footprints you can use. A good place to start is to talk to your team members and find out any areas where they struggle. For example, are there intersections that are congested, areas that require crisscrossing the warehouse, or inefficient racking that slows down the pick, pack, and ship process?

You will want to think through these pain points and visualize the new space and potential configurations, including adding automation. If you can reduce travel time or improve operational efficiency, it accelerates your fulfillment and reduces your labor costs.

Regulations

New locations may have new regulations. Make sure you investigate any permitting or regulatory requirements as soon as possible for your warehouse relocation. For example, some communities require a review of rack storage facilities for fire codes. There may also be regulations about density and material storage, safety features, and lighting.

An experienced material handling company can walk you through the process to ensure a smooth transition.

Timeline

Planning your relocation requires careful attention to timing. Downtime costs you money, so you want to make the move as efficient as possible. Using a company like Conesco with decades of experience with warehouse relocation services can help you create a realistic timetable to mitigate downtime. In most cases, a phased approach works best if you have to continue operating in the current space until the new space is ready.

Inventory

You will want to do a full inventory of your stock and eliminate obsolete or dead stock. Every item you have to move requires labor, so you only want to move items you will use in the future.

Besides the stock on shelves, you should think about pallet racking, mezzanines, conveyors, uprights, wire decks, shelving systems, and other equipment. If you need to sell used equipment or update it with new equipment, Conesco can help. We buy and sell new and used equipment at a high volume, enabling us to get great deals.

Labor

Do not underestimate the importance of using experienced warehouse relocation services experts when it comes to staffing. It takes specialized expertise and the right tools to do the job efficiently and safely. Experienced professionals will know the proper way to disassemble pallet racks, conveyors, and other equipment to avoid damage. If key components get damaged or parts get lost during disassembly and moving, it can derail your deadlines.

Conesco Storage Systems can help you plan your warehouse relocation and provide the warehouse staffing you need to make the transition safely and efficiently.

Testing and Training

After you move into the new location, you will also want to reserve time to do some test runs of your equipment, processes, and workflow to ensure everything works the way you intended. If you changed the layout to speed up fulfillment, for example, you will want to do an end-to-end trial run to make sure you meet your goals.

A new location also requires updated training for safety procedures, potential hazards, and locations of emergency exits and safety equipment. It is a good time to do a general refresher on safety and include any new information.

Choose Conesco Storage Systems

Since 1986, Conesco has been one of the nation’s largest buyers and sellers of warehouse equipment, specializing in warehouse relocation, decommissioning, and liquidation. With more than 150 years of combined warehouse experience, the Conesco team knows how to manage a relocation project efficiently and safely from start to finish.

Call the Conesco team at (303) 690-9591 or request a consultation online to discuss your warehouse relocation.