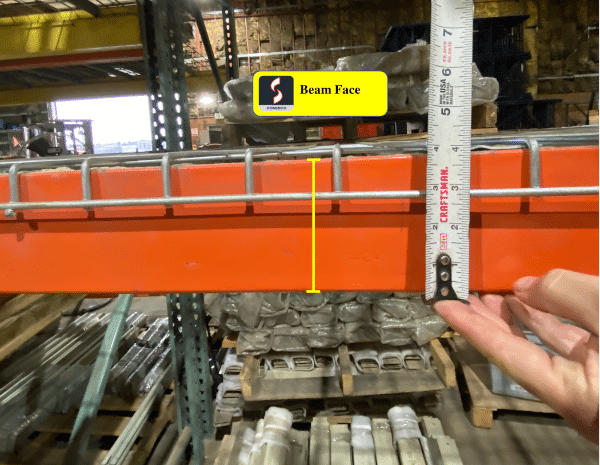

Measuring Cross Beams

To measure the pallet rack cross beams, first measure from the inside of one upright to the inside of the opposite upright. This inside dimension between the two up rights is the length of the beam. In many instances the measurement will be in one foot increments. For example, many common lengths of beams are 4’, 5’, 6’, 7’, 8’, 9’, etc. Occasionally some beams will fall in between one foot increments. These beams are usually made for custom pallet rack designs or are used for specific applications.

The other key measurement of the beam is the face size. The face of a cross beam is the side of the beam that faces out. The measurement is taken by measuring from the top of the beam to the bottom. This measurement coincides with the weight capacity of the beam. The bigger the face of the beam the more weight it can handle.

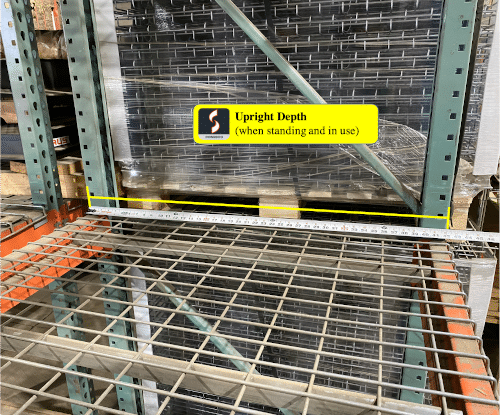

Measuring Uprights

There are four measurements that need to be taken when measuring a pallet rack upright. The first measurement is the depth of the upright. This is done by measuring from the outside edge of one side of the upright to the outside edge of the opposite side. Some common sizes are 36”, 42”, 46”, or 48”, but sizes can vary especially if the upright is a custom size. This is called “UPRIGHT DEPTH”

The next measurement is the size of the column of the upright. This part of the upright is where the beams lock into the upright and can be identified by the holes on it. First, measure the outside face of the column, then measure the inside face.

You should have two measurements that will give you the size of the column. For example, by measuring the face on one side and the face of the other I could get a 3”x3” measurement. The size of the column of the upright coincides with its weight capacity.

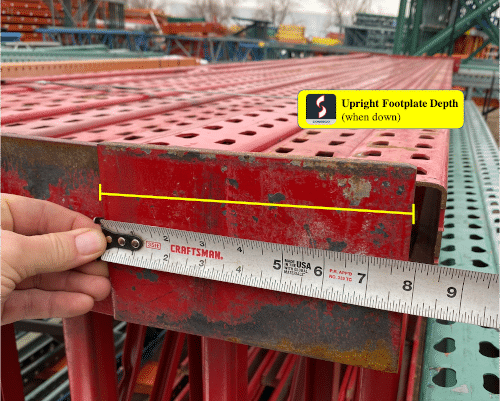

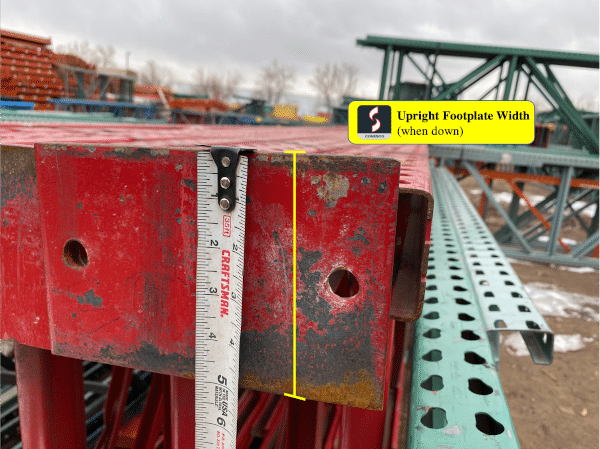

Next, measure the foot plate. The foot plate is what the upright columns sit on. They usually have holes that allow for them to be anchored to the ground. To get this measurement, measure the length and the width of the foot plate.

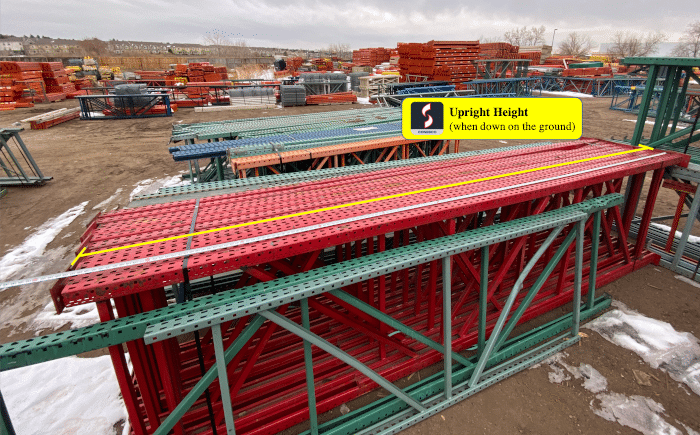

After measuring the foot plate, we take our final measurement of the upright to find the overall height. This is done by measuring from the ground to the top of the upright, or from the top of the upright to the ground. The height is usually in one foot increments, but could also fall in between. Some common sizes are 8’, 10’, 12’ and 16’.

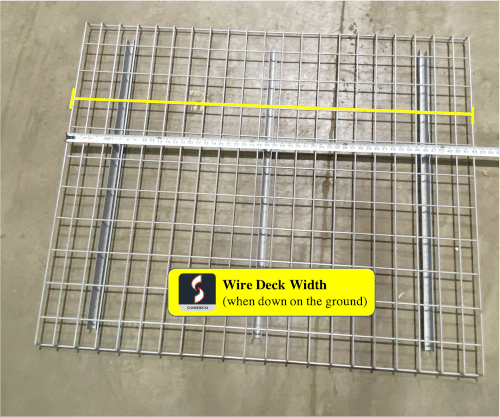

Measuring Wire Decking

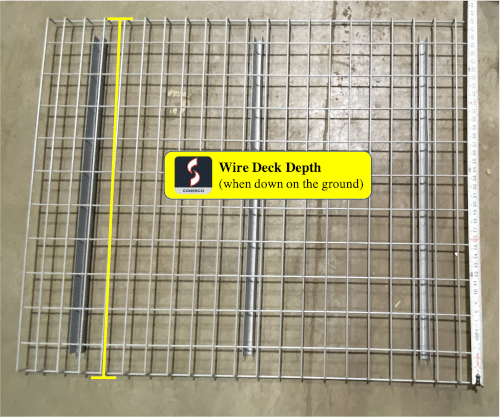

Measuring the wire decking is easier once you know the depth of the uprights that that the wire decking will be used with. For example, if the depth of the upright is 42”, then the depth of the wire deck would be 42”.

The only additional measurement needed is the width. This is found by measuring from the outside edge of one side of the deck to the other. One common size of wire decking is 42” deep and 46” wide, but sizes can vary.

Knowing these key measurements is necessary when trying to match existing pallet rack. If you have any questions about measuring pallet rack or are looking to buy pallet rack give us a call or check out our pallet rack section.