How Modern Warehouse Racking Systems Adapt to E-Commerce Demands

E-commerce continues to grow at a remarkable pace. Online sales are forecast to expand by more than 8% in 2025, adding up to $6.8 trillion. Sales volumes are expected to exceed $8 trillion by 2027.

With rising inventory, holding, and labor costs, warehouse operators must make smart decisions to manage their margins. However, shifts in consumer demand and product mixes are continually changing, and warehouse racking systems must be able to accommodate shifting demand without impacting efficiency.

E-Commerce Changes Warehouse Operations

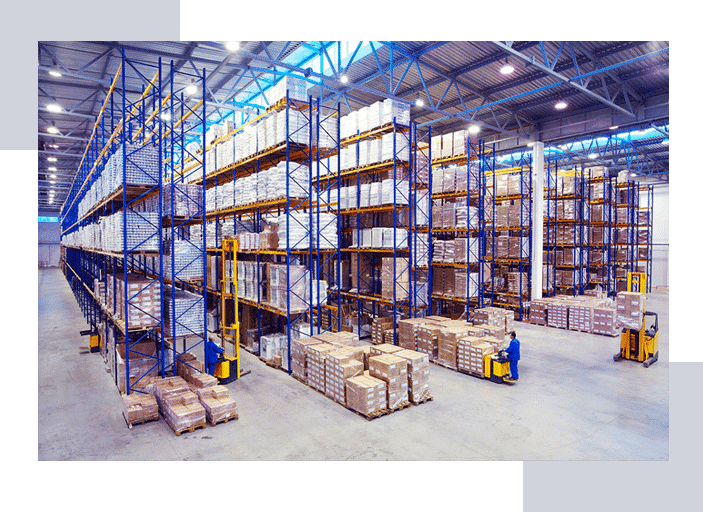

The traditional warehouse model was designed primarily for bulk storage and wholesale distribution, but that all changed with e-commerce. Today’s warehouses must handle higher order volumes with smaller quantities per order while maintaining rapid fulfillment capabilities for same-day or next-day delivery. This shift requires a rethinking of warehouse shelving racks and racking systems.

Modern facilities must also optimize for quick product retrieval, efficient order picking, and maximum space utilization–all while maintaining the flexibility to adapt to rapidly changing inventory needs. This complex set of requirements has driven significant innovation in warehouse racking systems.

How Warehouse Racking Systems Have Changed

Today’s warehouse racking systems incorporate several innovative features designed specifically for e-commerce.

Adjustable warehouse shelving racks with modular designs allow warehouses to modify storage configurations quickly as inventory changes. Flexible systems can be reconfigured to accommodate different product sizes and quantities, without requiring a complete overhaul.

High-density storage solutions maximize available space. Multi-level racking systems effectively utilize vertical space. Dynamic racking and flow systems, including carton flow racks and push-back systems, enhance product retrieval efficiency.

The right mix of warehouse racking systems and warehouse shelving racks optimizes workflow for faster fulfillment.

Adaptability to Market Dynamics

Scalability has become a crucial feature, enabling warehouses to expand or modify their storage capacity as demand grows.

Quick adjustment capabilities allow operations to respond to market conditions without significant disruption to ongoing operations. This adaptability extends to space utilization, with systems designed to maintain efficiency even during periods of fluctuating demand.

Adaptable racking systems allow for:

- Easy reconfiguration to accommodate changing or new products

- Scalability to manage seasonal inventory spikes or demand

- Adjustments for changing storage requirements

- Improved space utilization, including expansion of vertical storage

Integration with Automation Technologies

Efficient warehouse designs for e-commerce are increasingly integrating automation to improve workflow and lower labor costs. Automated storage and retrieval systems (AS/RS), automated guided vehicles (AGVs), and robotic picking systems create efficiency and streamline processes.

The compatibility with automation extends to warehouse management systems (WMS) and inventory tracking technologies.

Surprisingly, inventory management continues to plague e-commerce warehouses. The Institute of Supply Management (ISM) reports an average accuracy rate of just 91%, with lower-performing companies at 67%. Modern racking systems often incorporate features that support barcode scanning, RFID tracking, and other digital inventory management tools—enabling more accurate and real-time inventory tracking.

Enhanced Safety

Without proper safety protocols, warehouses can be dangerous places. In fact, the warehouse and transportation industries have the highest rates of serious illnesses and injuries among all occupations, according to the latest reports from the Government Accountability Office (GAO).

Modern warehouse racking systems and warehouse shelving racks include innovative safety features, such as:

- Load capacity indicators to prevent overloading

- Added stability with anti-collapse systems

- Integration with warehouse safety management systems

Future-Proofing Warehouse Operations

The right design, layout, and warehouse racking systems can help future-proof your warehouse operations.

As e-commerce operations become increasingly sophisticated, they can adapt to future needs.

Successful warehousing operations recognize that investing in adaptable racking systems is crucial for long-term success in the e-commerce landscape. These systems provide the foundation for efficient operations today while maintaining the flexibility to evolve with future market demands.

Optimize Your Warehouse Racking Systems for E-Commerce

If you need to upgrade, expand, reconfigure, or equip your e-commerce warehouse or fulfillment center, the experts at Conesco Storage Systems can help. We offer a complete lineup of new and used material handling equipment, including:

- Warehouse pallet racks

- Pallet flow racks

- Push back racks

- Drive in racks

- Stack racks

- Cantilever racks

- Mezzanines

- Carousels

- Warehouse shelving racks

- Lifts and machines

- Pick modules

- And more

We can handle all of your material handling needs and offer consulting services. Need help with warehouse design and planning, engineering documents and permitting, project management and expert installation services? We’ve got you covered.

Let us find the right warehouse racking systems for your e-commerce facility. Contact Conesco Storage Systems at (303) 690-9591 today.