Everyone’s heard of lockers. They’re those metal boxes in schools and gyms you’ve no doubt used at some point in life. We all know what lockers are but have you heard about wire storage lockers? These industrial lockers differ from the standard school lockers in several ways and can be a great benefit to warehouses, storage facilities, and even your home. What’s so great about wire storage lockers? We’ll tell you! Let’s review five unique benefits and uses for wire storage lockers.

Uses and Benefits of Wire Storage Lockers

1. Residential Storage

Wire storage lockers are perfect for garage storage, shed storage, or any other number of utility areas. If you’re a landlord, who needs to provide safe storage to your tenants, how about putting a couple of wire storage lockers in the lobby or basement of your building? Wire storage lockers are very versatile, so if you’ve been having problems with secure and convenient storage, it’s time to think about wire storage lockers.

2. Greenhouse/Growhouse Storage

Wire storage lockers can keep your plants and materials safe while still letting UV rays and other necessary components take care of your plant’s growth. Wire storage lockers will allow air and light to pass through while your plants remain protected. This has made them popular for dispensaries and other plants that grow plants of value.

3. Easy to Customize

You can build out a wire storage locker to suit the need you have. Wire storage lockers can be customized by size, type of wire, type of security, and wire lockers can be upgraded with more features and add-ons. This makes the perfect type of storage for any occasion.

4. A Secure Home for Expensive Equipment

Is your garage full of expensive tools? Do you have a vintage wine collection you want to keep around? Do you have specialty tools you want to keep away from untrained warehouse workers? Wire storage lockers are accessible and can fit anywhere, making them a great option for expensive equipment and other specialty items.

5. Take Control of your Inventory

Having issues with inventory? Try wire storage lockers. These types of lockers can keep people from messing with your organized tools or items. When you know nothing is coming in or going out without you knowing, you’ll step your inventory game.

Are you looking to buy and sell warehouse equipment? Get your questions answered here.

CONESCO serves the entire United States from multiple locations.

We get that question all the time! It depends on many factors such as:

- will the warehouse be shut down or,

- will it still be operating?

- How much material is there?

- Are the uprights bolted down to the ground?

Best practice is to give yourself multiple months of time in planning so that way you provide a buffer for your project to finish according to a timeline. Getting a full count of the materials and good pictures is a great way to start the process of evaluating the decommission of your warehouse.

It might be quicker than you think! The first step is to give us a call or have us call you. Once we have a good understanding of your unique situation, we typically provide a quote within 5 days and will schedule a time with you to have one of our team members come visit your site.

Yes! There are a few things that will need to happen in order to ensure everyone’s safety and some other items need communicated like an agreed upon timeline. It’s true, an operating warehouse will sometimes slow down a teardown project. But, we understand it’s necessary to avoid disruption of your business during the warehouse shelving and equipment removal process.

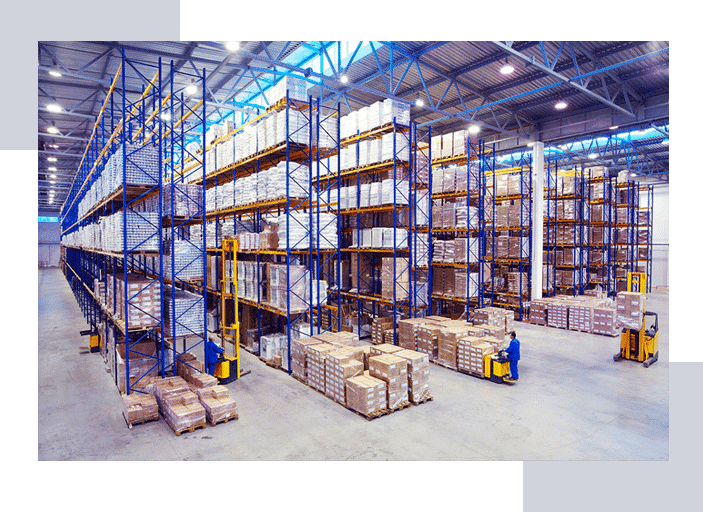

We are looking to purchase large quantities of pallet racking and most other warehouse equipment.

Our specialty is in used pallet racks (uprights, beams, wiredecks, pallet supports), pallet rack accessories (like guide/ guard rail, netting), conveyor systems, mezzanines, and pick modules. If your warehouse also includes different material like

- balers

- shrink wraps

- or lifts,

then we can buy/ remove those as well.

Sometimes material is in bad shape or is a very uncommon size or outdated brand. In some of these cases we do not purchase the materials, however we still can provide you with our teardown services to remove the materials from your warehouse. We encourage everyone to reach out so we can better understand what is in your warehouse and what your intentions are. Once we have a good understanding, we are happy to provide you with our recommendations, even if that means not using us.

Absolutely! Removing used warehouse equipment is a messy job. All debris will be properly disposed of and the floors swept.

No. Removing floor anchors does create holes but we take responsibility for grinding them down to be flush with the cement or fill them with cement epoxy.