How to Make the Most of Your Materials Handling Budget for 2024

For many operators, creating a warehouse budget for the new year ahead is a check-the-box activity. Smart operators, however, use a budget to look for ways to improve efficiency, reduce costs, and grow profitability.

Construction of new warehouses slowed significantly in the latter half of 2023, and activity is projected to decline further in 2024. This is forcing warehouse operators to create more efficient and optimal space within existing structures. When it comes to creating a materials handling budget for 2024, warehouse operators should look closely at their current processes, new ways of doing business, and whether they need to adapt to remain competitive.

As you consider your warehouse budget for 2024 or plan your end-of-year budget spending, here are some of the key steps to take.

Evaluate Your Current Materials Handling Processes

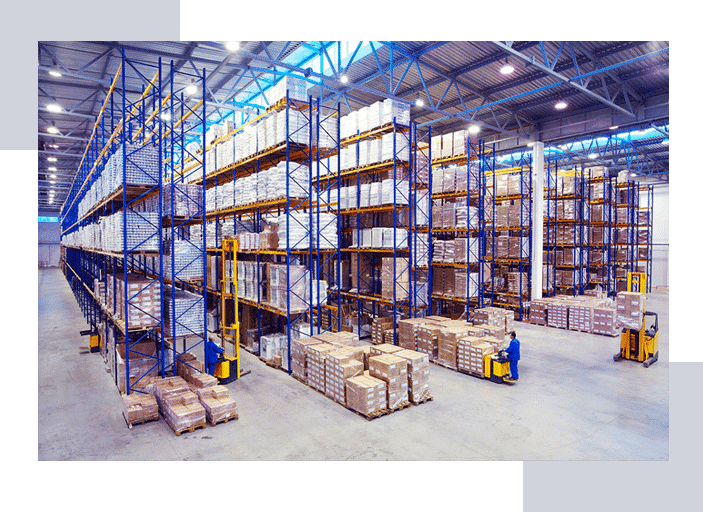

An efficient warehouse layout and the right equipment pay dividends. Now is always a good time to make sure you are using your space optimally.

Look critically at bottlenecks and redundancies that could be eliminated. Reorganizing your layout, adding warehouse automation, or installing the right pallet racks and conveyors can streamline operations. For example, travel time can account for as much as half of your total picking time and more than half of your labor costs. If you can create a more efficient layout or add the right equipment, your ROI can happen quickly.

Have your supervisors time key processes throughout the materials handling lifecycle, from receiving, storage, order picking, packing, and shipping, to identify any inefficiencies. Include your workers in the discussion. They know where the problems are.

As you put together your warehouse budget for 2024, look specifically at where replacing equipment or layout can improve throughput and lower labor costs.

Research Emerging Technologies

Once you understand your current situation, you need to examine emerging technology in equipment and automation. Will adding an updated conveyor system or automated storage and retrieval system (AS/RS) help meet your goals for 2024 (and beyond)?

Warehouse operators are deploying new strategies. Are you aware of them? Talk to experts, like the team at Conesco Storage Systems, who work with warehouse operators nationwide, to get ideas on evolving trends and new ways of doing business to increase efficiency.

The right automation and systems can help you dramatically reduce costs by:

- Optimizing space

- Improving inventory visibility

- Reducing labor costs

- Minimizing workplace accidents

Major retailers like Amazon and Walmart are investing heavily in automation, such as high-density AS/RS systems. Walmart, for example, opened what it called its next-generation fulfillment center in Indianapolis in June and plans to have five such operations by 2026. Amazon is increasing its use of automation and robots—now numbering about 750,000 in its warehouses.

Create Your Warehouse Budget

While building your warehouse budget for 2024, do not forget about anything leftover in 2023. Many companies have a use-it-or-lose-it attitude toward budgeting. End-of-year budget spending on improvements can set you up for success next year while potentially providing tax savings for all of 2023.

Your budget needs to strike a balance between current needs and future growth, so now is the time to think about the future and start planning.

If you have a tight budget, you may want to consider used equipment. Conesco is an industry leader in decommissioning warehouses and handling liquidations. This results in significant amounts of high-quality used equipment—some of which are almost brand new. You can often find the right piece of equipment to improve your operation without having to break the bank.

Execute Your Plan

With your budget in place, it is time to execute.

Work with a supplier that does more than just sell you products. You want warehouse operations experts who can guide you with best practices from the industry’s top operators.

The team at Conesco has been around since 1986 and has a deep understanding of the complexities of warehouse and inventory management. With hundreds of years of combined experience in pallet racking, material handling, and operations, Conesco can help you find the equipment and warehouse layout you need to optimize your materials handling budget.

Here is to a prosperous 2024! If we can help, get in touch.

Make the most of your materials handling budget in 2024. Call the Conesco team at (303) 690-9591 or request a consultation online.