Warehouse Pallet Rack Layout Planning for Space and Efficiency

Strategic pallet rack layout planning increases storage capacity by 25-40% while improving operational efficiency and safety. Learn the... Read More

Pallet Rack Load Capacity Guide for Warehouse and Facility Teams

Navigate the complexity of pallet rack capacity selection with this practical guide. Learn how post gauge, frame depth,... Read More

Pallet Racking Inspection Procedures for Warehouse Safety

Systematic pallet racking inspections prevent catastrophic failures and costly downtime. This comprehensive guide covers equipment requirements, measurement standards,... Read More

New Jersey Storage Rack Permit Requirements and Compliance Guide

Storage rack permits in New Jersey require extensive documentation across drawing requirements and engineering certifications. This guide walks... Read More

Optimizing Conveyor and Pallet Rack Integration for Material Flow

Strategic integration of conveyors and pallet racks transforms warehouse operations through improved throughput, reduced handling costs, and optimized... Read More

Colorado Pallet Racking Compliance Guide for Warehouses

Your new pallet racking system looks impressive. The last beam is in place, the anchors are tightened, and... Read More

New vs. Used Pallet Racking: Making the Right Investment Decision

Warehouse managers must assess a vital choice when expanding storage space: should they invest in new pallet racking... Read More

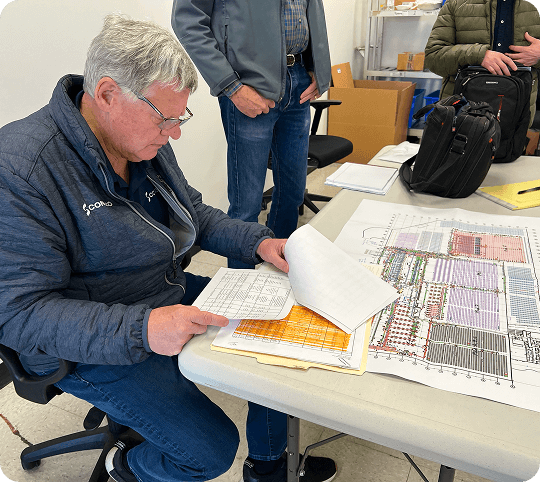

Buy used warehouse equipment in Ft. Worth, TX

Looking to buy used warehouse equipment in Dallas, TX? You are in the right place. Conesco has a... Read More

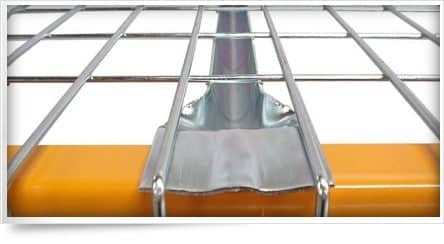

Warehouse Wire Decking Solutions by Conesco

What Is Wire Decking? What is Wire DeckingWire decking is used on selective pallet rack to support the... Read More

How To Measure A Pallet Rack

How to Measure Pallet Rack Components Adding new pallet rack to an existing system? Matching the right... Read More

Cost-Saving Tips for Investing in Durable Warehouse Pallet Racks

You hear horror stories about buying warehouse racking second-hand. You don’t know how it’s been cared for, how... Read More

Innovations in Industrial Material Handling Equipment

You hear horror stories about buying warehouse racking second-hand. You don’t know how it’s been cared for, how... Read More