Quantities as of 9.18

Off-site Inventory

Capitalize on quality pre-owned material handling equipment available across the USA! Don’t see what you need? Get in touch to leverage our global network of partners to find new & used options to save you time & money. From warehouse planning, drawing, engineering, permitting to installation– Conesco has you covered.

Increased Efficiency

Identify & Hit Your Needs

Create Scalability and Accommodate Your Growth & Expansion

Perris, CA 92570

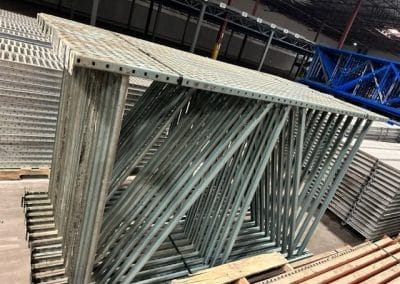

| Qty | Product | Size | Type |

|---|---|---|---|

| 86 | Upright | 42″ x 24′ x 3″ x 3″ | NS&TearDrop Interack30 75, green, 8″ x 8″ FP |

| 4 | Upright | 44″ x 16′ x 3″ x 3″ | IL TearDrop |

| 891 | Upright | 44″ x 25′ x 3″ x 3″ | TearDrop; 12″ x 12″ x 3/8″ FP; Green; HMH14 ga |

| 970 | Upright | 44″ x 25′ x 3″ x 3″ | TearDrop; 8″ x 8″ x 3/8″ FP; Green; Double Reinf. to 72″; HMH13 ga |

| 48 | Beam | 3″ x 60″ x 1 5/8″ | NS |

| 18 | Beam | 3 3/4″ x 94″ x 1 5/8″ | TearDrop |

| 530 | Beam | 3 5/16″ x 106″ x 1 5/8″ | NS; IL; STAMP -311-; Green |

| 7,431 | Beam | 3″ x 108″ x 1 5/8″ | Teardrop Orange |

| 2,784 | Beam | 3 3/8″ x 108″ x 1 5/8″ | TearDrop 3 pin connectors; Orange |

| 130 | Beam | 4.75″ x 144″ x 1 5/8″ | TearDrop; 4 pin connectors; Orange |

| 326 | Beam | 5″ x 144″ x 1 5/8″ | TearDrop; Orange; HMH50; 3 pin connectors |

| 410 | Wire Deck | 42″ x 46″ | DWF; 3 Channel |

| 15,480 | Wire Deck | 44″ x 52″ | DWF; 3 Channel |

| 60 | Row Spacer | 6″ | |

| 2,069 | Row Spacer | 12″ | |

| 60 | Row Spacer | 15″ | |

| 60 | Row Spacer | 18″ | |

| 114 | Row Spacer | 24″ | |

| 60 | Row Spacer | 32″ |

A- Denver, CO 80238

| QTY | Item | Size | Type/Comments |

| 25 | Upright | 36″ x 18′ x 3″x3″ | Teardrop; 4-1/2″ x 3″ fp |

| 224 | Beam | 5″ x 96″ x 1-5/8″ | NewStyle Teardrop |

| 120 | Beam | 96″ | NewStyle Teardrop; backstop |

| 224 | Wire Deck | 36″ x 46″ | Double WaterFall; 3-channel |

| 1 | Netting | 18′ x 200′ | Black; nylon |

| 16 | Column Protector | 24″ | Standard; bolt-on |

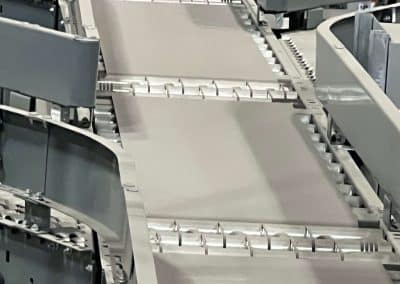

Fontana, CA 92336

| Qty | Item | Size | Type/Comments |

| 231 | Gravity Roller | 24″ | Qty in ft.; Intelligrated GRS |

| 28 | Gravity Wheel | 24″ | Qty in ft.; Intelligrated GWC |

| 1,408 | Accuglide Zone Flex | 24″ | Qty in ft.; Intelligrated ACGZF |

| 526 | Accuglide Zone Flex | 30″ | Qty in ft; Intelligrated ACGZF |

| 384 | Belt on Roller (BOR) | 24″ | Qty in ft.; Intelligrated BRB |

| 75 | Belt on Roller (BOR) | 30″ | Qty in ft.; Intelligrated BRB |

| 26 | Slider Bed | 24″ | Qty in ft.; Intelligrated BRB |

| 20 | V Belt Live Roller | 30″ | Qty in ft; Intelligrated VB |

| 1,868 | MDR Rollers | 24″ | Qty in ft.; Intelligrated MDR |

| 103 | MDR Rollers | 30″ | Qty in ft.; Intelligrated MDR |

| 405 | Trash Conveyor | 30″ | Qty in ft.; Intelligrated ECC – empty corrugate conveyor |

| 194 | Trash Conveyor | 48″ | Qty in ft.; Intelligrated ECC – empty corrugate conveyor |

| 6 | Brake Meter Belt | 24″ x 9’L | 9′ units; Intelligrated BMB |

| 4 | SKEW | 24″ | 12′ units; alignment beds |

| 1 | Sorter | 360′ of pop up wheel ISPWS sorter with 24 30″ diverts | |

| 56 | 24″ | Qty in ft.; pop up wheel ISPWS | |

| 58 | 24″ | Qty in ft.; pop up wheel ISPWS | |

| 58 | 24″ | Qty in ft.; pop up wheel ISPWS | |

| 77 | 24″ | Qty in ft.; pop up wheel ISPWS | |

| 53 | 24″ | Qty in ft.; pop up wheel ISPWS | |

| 58 | 24″ | Qty in ft.; pop up wheel ISPWS | |

| 24 | Divert – 30 degree | 30″ | Qty in units |

| 1 | Curve – 45 degree | 24″ | Qty in units |

| 7 | Curve – 90 degree | 24″ | Qty in units |

| 1 | Curve – 180 degree | 24″ | Qty in units |

| 3 | Belt Curve | 21.5″ to 24.5″ | Qty in units; Intelligrated PBC |

| 1 | Tote Aligner | 24″ x 5′ | Qty in units; Intralox carton aligner |

| 1 | Merge | 30″ x 15′ | Two to one merge |

West Jefferson, OH 43162

| Qty | Item | Size | Type/Comments |

| 231 | Gravity Roller | 24″ | Qty in ft.; Intelligrated GRS |

| 52 | Gravity Wheel | 24″ | Qty in ft.; Intelligrated GWC |

| 1,400 | Accuglide Zone Flex | 24″ | Qty in ft.; Intelligrated ACGZF |

| 786 | Accuglide Zone Flex | 30″ | Qty in ft.; Intelligrated ACGZF |

| 379 | Belt on Roller (BOR) | 24″ | Qty in ft.; Intelligrated BRB |

| 101 | Belt on Roller (BOR) | 30″ | Qty in ft.; Intelligrated BRB |

| 26 | Slider Bed | 24″ | Qty in ft.; Intelligrated BRB |

| 26 | Slider Bed | 30″ | Qty in ft.; Intelligrated BRB |

| 6 | V Belt Live Roller | 24″ | Qty in ft.; Intelligrated VB |

| 20 | V Belt Live Roller | 30″ | Qty in ft.; Intelligrated VB |

| 28 | MDR Rollers | 30″ | Qty in ft.; Intelligrated MDR |

| 405 | Trash Conveyor | 30″ | Qty in ft.; Intelligrated ECC – empty corrugate conveyor |

| 267 | Trash Conveyor | 48″ | Qty in ft.; Intelligrated ECC – empty corrugate conveyor |

| 6 | Brake Meter Belt | 24″ x 9’L | 9′ units; Intelligrated BMB |

| 3 | SKEW | 24″ | 12′ units; alignment beds |

| 1 | Sorter | 24″ | 366′ of pop up wheel ISPWS sorter with 25 24″ diverts |

| 25 | Divert – 30 degree | 30″ | Qty in units |

| 1 | Curve – 45 degree | 24″ | Qty in units |

| 1 | Curve – 45 degree | 30″ | Qty in units |

| 1 | Curve – 90 degree | 24″ | Qty in units |

| 7 | Curve – 90 degree | 30″ | Qty in units |

| 1 | Curve – 180 degree | 24″ | Qty in units |

| 4 | Belt Curve | 24″ to 27″ | Qty in units; Intelligrated PBC |

| 1 | Tote Aligner | 24″ x 5′ | Qty in units; Intralox carton aligner |

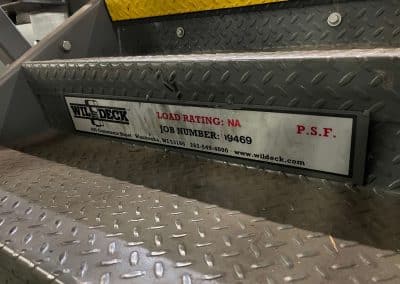

| 1 | Crossover | 4’W x 24’L | Stairs (19 steps) each end; 10′ clear; 4′ x 24′ bar grate walkway; Wildeck Job #43337 |

| 1 | Merge | 30″ x 15′ | Two to one merge |

P- Denver, CO 80239

| Qty | Product | Size | Type |

| 369 | Upright | 36″ x 16′ x C3 | Structural with TearDrop connections; Blue; 5″x7″or 3″x5″ FP; 2-4 BH; some 6″-12″ bullnose |

| 62 | Upright | 36″ x 20′ x C3 | Structural with TearDrop connections; Blue; 5″x7″or 3″x5″ FP; 2-4 BH; some 6″-12″ bullnose |

| 18 | Beam | 3 1/2″ x 96″ x 15/8 | TearDrop; Yellow |

| 1380 | Beam | 4″ x 98″ x 1 5/8″ | TearDrop; Red |

| 54 | Beam | 4″ x 120″ x 1 5/8″ | TearDrop; Red |

| 30 | Beam | 4 3/4″ – 5 1/2″ x 98″ x x 1 5/8″ | TearDrop; Red |

| 638 | Beam | 5″ x 102″ x 1 5/8″ | TearDrop; Red |

| 158 | Beam | 5″ x 108″ x 1 5/8″ | TearDrop; Red |

| 302 | Beam | 5 1/2″ x 120″ x 1 5/8″ | TearDrop; Red |

| 2810 | Wire Deck | 36″ x 46″ | DWF; 3-channel |

| 521 | Row Spacer | 14″ | |

| 78 | Cantilever Arm | 48″ x 4″ x 1 1/2″ | |

| Outside Cantilever | |||

| 7 | Tower | 16′ x 4″ x 10″ | |

| 7 | Base | 62″ x 5″ x 8″ | Bolted; single side |

| 28 | Arm | 48″ | |

| 12 | X Brace | 42″ x 60″ |

Boise, ID 83702

| Qty | Item | Size | Type/Comments |

| 32 | Upright | 44″ x 4′ x 3″ x 3″ | Teardrop |

| 32 | Upright | 44″ x 9′ x 3″ x 3″ | Teardrop |

| 33 | Upright | 44″ x 11′ x 3″ x 3″ | Teardrop |

| 30 | Upright | 44″ x 14′ x 3″ x 3″ | Teardrop |

| 34 | Beam | 4″ x 48″ x 1-5/8″ | Teardrop |

| 366 | Beam | 4″ x 96″ x 1-5/8″ | Teardrop |

| 414 | Beam | 4″ x 144″ x 1-5/8″ | Teardrop |

| 926 | Wire Deck | 44″ x 46″ | DWF; 3-channel |

| 4 | Tower | est 10′ tall | Interlake |

| 4 | Base | 48″ | Interlake |

| 24 | Arm | 48″ | Interlake |

| 4 | X Brace | tbd | Interlake |

| 16 | Horiz. Brace | tbd | Interlake |

E- Louisville, KY 40299

| QTY | Item | Size | Style/Comments |

| 295 | Span Track | 12.5″ x 15′ | 2″ centers |

| 56 | Span Track | 12.5″ x 15′ 8″ | 2″ centers |

| 924 | Span Track | 12.5″ x 16′ | 2″ centers |

| tbd | Hangers | tbd | |

| 58 | Upright | 42” x 22’ high x 3” x 3” | Interlake NewStyle |

| 31 | Upright | 42” x 14’ high x 3” x 3” | Interlake NewStyle |

| 13 | Extensions | 42” x 4’ high x 3” x 3” | Interlake NewStyle |

| 52 | Beam | 4.5” x 92” x 1 5/8″ | Interlake NewStyle |

| 56 | Beam | 5” x 99” x 1 5/8″ | Interlake NewStyle |

| 152 | Beam | 5 3/4” x 96” x 1 5/8″ | Interlake NewStyle |

| 12 | Upright | 42” x 10’ x 4”xC3 | 8”x7” FP |

| 96 | Upright | 44” x 22’ x C4 | 5”x7” FP |

| 46 | Upright | 48” x 8’ x 3’x1-5⁄8” | |

| 123 | Upright | 49” x 22’ x C3 | Heavy duty w/ bullnose, 4”x9-1⁄2” FP |

| 56 | Upright | 50” x 28’ x C4 | w/ bullnose, 5”x9-1⁄2” FP |

| 12 | Upright | 54” x 10’ 4”xC3 | |

| 20 | Upright | 60” x 8’ x 3”x1-5⁄8” | 3”x3” FP |

| 108 | Monopost | 22’ x 3″ | 5”x7” FP |

| 1,200 | Beam | C4 x 96” | 4 bolt connector |

| 100 | Beam | C4 x 96” | drop 1-1⁄2” |

| 100 | Beam | C5 x 96” | drop 1-7⁄8” |

| 150 | Beam | C4 x 120” | |

| 800 | Wire Deck | 44″ x 46″ | DWF, 3-chnl, for structural beam |

| 40 | Wire Deck | 44″ x 46″ | DWF, 3-chnl, for roll form |

| 2,054 | Double Pallet Support | 96” x 2″x2″ |

U- Louisville, KY 40219

| Qty | Product | Size | Type |

| 4133 | Pick Mod A | 30′ 4″W x 136′ 3″L | Footprint of 4,133 sq. ft.; total of 12,399 sq. ft. on all 3 levels; rack-supported module; various combinations of carton flow shelves and pallet flow lanes on each level |

| 60 | Beam | 5″ x 45″ x 1 5/8″ | New Style; grey |

| 20 | Beam | 5″ x 45″ x 1 5/8″ | Universal; grey |

| 10 | Beam | 8″ x 45″ x 1 5/8″ | New Style; grey |

| 84 | Beam | 5″ x 48″ x 1 5/8″ | New Style; grey |

| 28 | Beam | 5″ x 48″ x 1 5/8″ | Universal; grey |

| 14 | Beam | 8″ x 48″ x 1 5/8″ | New Style; grey |

| 50 | Beam | 8″ x 96″ x 1 5/8″ | New Style; grey |

| 68 | Beam | 9″ x 152″ | New Style; grey; J hook cross-aisle |

| 258 | Row Spacer | 22″ | |

| 454 | Pallet Flow Track | 102″L | Single plastic wheel; stops |

| 2 | Carton Flow Shelf | 48″W x 106″D | Clip-in style; 3 lanes ea. with 4 roller tracks per lane |

| 38 | Carton Flow Shelf | 96″W x 106″D | Clip-in style; 6 lanes ea. with 4 roller tracks per lane |

| 1 | Conveyor Components | See conveyor quantities below | |

| 8266 | B Deck | Qty in sq. ft. – levels 2 and 3 | |

| 8266 | Resin Deck | 48″W x 96″L x 3/4″H | Qty in sq. ft. – levels 2 and 3 |

| 544 | Lights | Qty in lin. ft.; levels 1 and 2 | |

| 1088 | Sprinkler Pipe | Qty in lin. ft.; levels 1 and 2 | |

| 2 | Stairway | Wildeck Stair Tower | |

| 4133 | Pick Mod B | 30′ 4″W x 136′ 3″L | Footprint of 4,133 sq. ft.; total of 12,399 sq. ft. on all 3 levels; rack-supported module; various combinations of carton flow shelves and pallet flow lanes on each level |

| 84 | Upright | 42″ x 32′ x 3″ x 3″ | New Style #75; double reinf. to 144″; 3″ x 6″ FP; dark blue; slotted sides |

| 60 | Beam | 5″ x 45″ x 1 5/8″ | New Style; grey |

| 20 | Beam | 5″ x 45″ x 1 5/8″ | Universal; grey |

| 10 | Beam | 8″ x 45″ x 1 5/8″ | New Style; grey |

| 84 | Beam | 5″ x 48″ x 1 5/8″ | New Style; grey |

| 28 | Beam | 5″ x 48″ x 1 5/8″ | Universal; grey |

| 14 | Beam | 8″ x 48″ x 1 5/8″ | New Style; grey |

| 50 | Beam | 8″ x 96″ x 1 5/8″ | New Style; grey |

| 68 | Beam | 9″ x 152″ | New Style; grey; J hook cross-aisle |

| 258 | Row Spacer | 22″ | |

| 454 | Pallet Flow Track | 102″L | Single plastic wheel; stops |

| 2 | Carton Flow Shelf | 48″W x 106″D | Clip-in style; 3 lanes ea. with 4 roller tracks per lane |

| 38 | Carton Flow Shelf | 96″W x 106″D | Clip-in style; 6 lanes ea. with 4 roller tracks per lane |

| 1 | Conveyor Components | See conveyor quantities below | |

| 8266 | B Deck | Qty in sq. ft. – levels 2 and 3 | |

| 8266 | Resin Deck | 48″W x 96″L x 3/4″H | Qty in sq. ft. – levels 2 and 3 |

| 544 | Lights | Qty in lin. ft.; levels 1 and 2 | |

| 1088 | Sprinkler Pipe | Qty in lin. ft.; levels 1 and 2 | |

| 2 | Stairway | Wildeck Stair Tower | |

| 4133 | Pick Mod C | 30′ 4″W x 136′ 3″L | Footprint of 4,133 sq. ft.; total of 12,399 sq. ft. on all 3 levels; rack-supported module; various combinations of carton flow shelves and pallet flow lanes on each level |

| 86 | Upright | 42″ x 32′ x 3″ x 3″ | New Style #75; double reinf. to 144″; 3″ x 6″ FP; dark blue; slotted sides |

| 60 | Beam | 5″ x 45″ x 1 5/8″ | New Style; grey |

| 20 | Beam | 5″ x 45″ x 1 5/8″ | Universal; grey |

| 10 | Beam | 8″ x 45″ x 1 5/8″ | New Style; grey |

| 84 | Beam | 5″ x 48″ x 1 5/8″ | New Style; grey |

| 28 | Beam | 5″ x 48″ x 1 5/8″ | Universal; grey |

| 14 | Beam | 8″ x 48″ x 1 5/8″ | New Style; grey |

| 50 | Beam | 8″ x 96″ x 1 5/8″ | New Style; grey |

| 68 | Beam | 9″ x 152″ | New Style; grey; J hook cross-aisle |

| 258 | Row Spacer | 22″ | |

| 454 | Pallet Flow Track | 102″L | Single plastic wheel; stops |

| 2 | Carton Flow Shelf | 48″W x 106″D | Clip-in style; 3 lanes ea. with 4 roller tracks per lane |

| 38 | Carton Flow Shelf | 96″W x 106″D | Clip-in style; 6 lanes ea. with 4 roller tracks per lane |

| 3 | Barrell Fan | 26″ Fan, 33 1/2″ OAD x 18″ D | Patterson; with yoke mount |

| 1 | Conveyor Components | See conveyor quantities below | |

| 8266 | B Deck | Qty in sq. ft. – levels 2 and 3 | |

| 8266 | Resin Deck | 48″W x 96″L x 3/4″H | Qty in sq. ft. – levels 2 and 3 |

| 544 | Lights | Qty in lin. ft.; levels 1 and 2 | |

| 1088 | Sprinkler Pipe | Qty in lin. ft.; levels 1 and 2 | |

| 2 | Stairway | Wildeck Stair Tower | |

| 4133 | Pick Mod D | 30′ 4″W x 136′ 3″L | Footprint of 4,133 sq. ft.; total of 12,399 sq. ft. on all 3 levels; rack-supported module; various combinations of carton flow shelves and pallet flow lanes on each level |

| 86 | Upright | 42″ x 32′ x 3″ x 3″ | New Style #75; double reinf. to 144″; 3″ x 6″ FP; dark blue; slotted sides |

| 60 | Beam | 5″ x 45″ x 1 5/8″ | New Style; grey |

| 20 | Beam | 5″ x 45″ x 1 5/8″ | Universal; grey |

| 10 | Beam | 8″ x 45″ x 1 5/8″ | New Style; grey |

| 84 | Beam | 5″ x 48″ x 1 5/8″ | New Style; grey |

| 28 | Beam | 5″ x 48″ x 1 5/8″ | Universal; grey |

| 14 | Beam | 8″ x 48″ x 1 5/8″ | New Style; grey |

| 0 | Beam | 5″ x 96″ x 1 5/8″ | New Style; grey |

| 32 | Beam | 5″ x 96″ x 1 5/8″ | Universal; grey |

| 50 | Beam | 8″ x 96″ x 1 5/8″ | New Style; grey |

| 68 | Beam | 9″ x 152″ | New Style; grey; J hook cross-aisle |

| 258 | Row Spacer | 22″ | |

| 454 | Pallet Flow Track | 102″L | Single plastic wheel; stops |

| 2 | Carton Flow Shelf | 48″W x 106″D | Clip-in style; 3 lanes ea. with 4 roller tracks per lane |

| 38 | Carton Flow Shelf | 96″W x 106″D | Clip-in style; 6 lanes ea. with 4 roller tracks per lane |

| 8 | Barrell Fan | 26″ Fan, 33 1/2″ OAD x 18″ D | Patterson; with yoke mount |

| 1 | Conveyor Components | See conveyor quantities below | |

| 8266 | B Deck | Qty in sq. ft. – levels 2 and 3 | |

| 8266 | Resin Deck | 48″W x 96″L x 3/4″H | Qty in sq. ft. – levels 2 and 3 |

| 544 | Lights | Qty in lin. ft.; levels 1 and 2 | |

| 1088 | Sprinkler Pipe | Qty in lin. ft.; levels 1 and 2 | |

| 2 | Stairway | Wildeck Stair Tower | |

| 0 | Clear Span Mezzanines | ||

| 2072 | Clear Span Mezzanine | 37’W x 56’L x 15′ Clear | Qty in sq. ft; B Deck and Resin Dek; 1 ladder |

| 0 | Conveyor Support Grids | ||

| 3600 | Conveyor Support Grid | 30’L x 120′ L x 11′ Clear | Qty in sq. ft; open structural grid |

| 20000 | Conveyor Support Grid | 50’W x 350’L x 20.5′ Clear; L shaped with one additional 50’W x 100’L section | Qty in sq. ft; open structural grid; 3’W x 350’L catwalk with bar grate |

| 1358 | Plank Grating | 10.5″ x 102″ & 12″ x 102″ | QTY in pieces |

| 77 | Guard Rail | 8’L x 14″H | Yellow |

| 147 | Guard Rail Post | 18″ x 4″ x 4″ | Yellow; 10″ x 10″ BP |

| 2 | Barrell Fan – Under Mez. | 26″ Fan, 33 1/2″ OAD x 18″ D | Patterson; with mount |

| 2 | Extendable Truck Loader | 47″OAW x 10’L retracted | SRS Model UNL-43-8110; 21″ belt |

| 9 | Flexible Gravity Conveyor | 31″W x 25’L Compacted | Best Flex 300; skatewheel |

| 41 | Work Table – Wood Top | 30″W x 72″L x 34″H | Steel frame; adjustable legs |

| 25 | Work Table – Wood Top | 28″W x 60″L x 34″H | Steel frame; adjustable legs |

| 20 | Work Table – Laminate Top | 28″W x 55″L x 34″H | Steel fixed frame |

| 12 | Cantilever Tower | 12’H x 8″-12″D x 4″W | |

| 12 | Cantilever Base | 39″ x 8″W x 12″H | Base 51″ OAL; welded to tower |

| 39 | Arm | 39″ x 2 3/4″ diameter | Round tube |

| 11 | X Brace | 44″W x 47″H | Includes horizontal spacers |

| 65 | Locker Bank – Large | 36″W x 84″T x 18″D | Qty in banks; each bank is 2 openings high x 3 openings wide |

| 4 | Locker Bank – Small | 36″W x 78″T x 12″D | Qty in banks; each bank is 6 openings high x 3 openings wide |

| 4 | Case Erector | Lantech | |

| 2 | Case Sealer | Pearson Model CS30 | https://www.youtube.com/watch?v=qUtYyxYTwEM |

| 0 | Wire Cage | ||

| 0 | Wirecrafter Cage | L-Shaped – 23’W x 100’L x 10’H | Qty in linear ft. |

| 0 | Gravity Conveyor | ||

| 2580 | Gravity Roller | 18 1/2″W; 10’L beds; 1 3/8″ rollers 3″ o.c. | Qty in ft; Intelligrated; in modules |

| 9921 | Gravity Roller | 30 1/2″W; 12’L beds; 1 3/8″ rollers 3″ o.c. | Qty in ft; Intelligrated |

| 14 | Gravity Curve | 30 Degree; 24 1/2″ | |

| 16 | Gravity Curve | 60 Degree; 24 1/2″ | Wheel curve |

| 2 | Gravity Curve | 60 Degree; 36 1/2″ | Wheel curve |

| 26 | Gravity Spur | 30 Degree; 36 1/2″ | Roller Spur |

| 22 | Gravity Gate | 30 1/2″ | Roller Gate |

| 4 | Gravity Gate | 36 1/2″ | |

| 12 | Gravity Chute | 20′ Long | |

| 0 | Powered Conveyor | ||

| 1500 | Belt on Roller (BOR) | 24 1/2″ | Qty in ft; Intelligrated; in modules |

| 2338 | Belt on Roller (BOR) | 30 1/2″ | Qty in ft; Intelligrated |

| 2169 | Belt on Roller (BOR) | 36 1/2″ | Qty in ft; Intelligrated |

| 1110 | IntelliQ Accumulation | 30 1/2″ | Qty in ft; Intelligrated; 36″ zones |

| 4212 | IntelliQ Accumulation | 36 1/2″ | Qty in ft; Intelligrated; 36″ zones |

| 312 | Belt on Slider (Slider Bed) | 30 1/2″ | Qty in ft; Intelligrated |

| 275 | Belt on Slider (Slider Bed) | 36 1/2″ | Qty in ft; Intelligrated |

| 1000 | Trash Conveyor (Slider Bed) | 42 1/2″ | Qty in ft; Intelligrated; 6″ sides |

| 16 | MDR Dual Transfer | 120 FPM | Intelligrated |

| 5 | Brake Meter Belt | 28″ x 9′ | Intelligrated |

| 18 | Brake Meter Belt | 34″ x 9′ | Intelligrated |

| 1 | IntelliSort Sorter | 36 1/2″ x 225′ (est. length) | 13 RH diverts + 7 future; Intelligrated |

| 1 | Intellisort Sorter | 36 1/2″ x 226′ (est. length) | 14 LH diverts + 2 future; Intelligrated |

| 3 | Low Speed Sorter | 36 1/2″ x 203′ | 60 dual diverts; 90 degree |

| 2 | Scanner | SICK OPS 690 3 side scan | |

| 3 | Curve | 30 Degree; 30 1/2″ | |

| 1 | Curve | 30 Degree; 36 1/2″ | |

| 8 | Curve | 45 Degree; 30 1/2″ | |

| 2 | Curve | 45 Degree; 36 1/2″ | |

| 3 | Curve | 60 Degree; 30 1/2″ | |

| 22 | Curve | 60 Degree; 36 1/2″ | |

| 9 | Curve | 90 Degree; 30 1/2″ | |

| 37 | Curve | 90 Degree; 36 1/2″ | |

| 8 | Curve | 180 Degree; 30 1/2″ | |

| 16 | Curve | 180 Degree; 36 1/2″ | |

| 1 | Spur | 30 Degree; 30 1/2″ | |

Jonesville, SC 29353

| Qty | Product | Size | Type |

| 5 | Upright | 36″ x 38′ 6″ x 3″ x 3″ | ILTD #75; 8″ x 8″ FP; 4 hole |

| 35 | Upright | 36″ x 12’2″ x 3″ x 3″ | ILTD #75; 8″ x 8″ FP; 4 hole, needs Footplate |

| 6 | Upright | 42″ x 16′ x 3″ x 2″ | TD |

| 4 | Upright | 42″ x 17.5′ x 3″ x 2 1/2″ | Ridg-U-Rak; white |

| 28 | Upright | 42″ x 21′ x 3″ x 3″ | Mecalux bolted; double reinf. to 10′ |

| 10 | Upright | 42″ x 20′ x 3″ x 3″ | TD |

| 17 | Upright | 42″ x 20′ x 3″ x 3″ | NS; 3″ x 4 1/2″ FP |

| 47 | Upright | 42″ x 24′ x 3″ x 3″ | NS; 3″ x 4 1/2″ FP |

| 8 | Upright | 42″ x 23.5′-24.5′ x 3″ x 3″ | Ridg-U-Rak; various leg configs; white |

| 30 | Upright | 42″ x 29′ x 3″ x 2 1/2″ | Ridg-U-Rak; various leg configs; white |

| 2 | Upright | 42″ x 35′ x 3″ x 3″ | Ridg-U-Rak; straight leg; white |

| 4 | Upright | 42″ x 35′ x 3″ x 3″ | Ridg-U-Rak; 10″ setback at 60″; white |

| 3 | Upright | 42″ x 35′ x 3″ x 3″ | Ridg-U-Rak; 10″ cant at 51″; white |

| 5 | Upright | 60″ x 30′ x 3″ x 3″ | Ridg-U-Rak; white |

| 179 | Upright | 60″ x 12′ 2″ x 3″ x 3″ | ILTD #75; 8″ x 8″ FP; 4 hole, needs FP |

| 21 | Upright | 60″ x 38′ 6″ x 3″ x 3″ | ILTD #75; 8″ x 8″ FP; 4 hole |

| 10 | Beam | 2 3/4″ x 96″ x 1 5/8″ | TD/NS |

| 60 | Beam | 4″ x 96″ x 1 5/8″ | Ridg-U-Rak |

| 1,436 | Beam | 4″ x 99″ x 1 5/8″ | Ridg-U-Rak |

| 24 | Beam | 5″ x 143″ x 1 5/8″ | Ridg-U-Rak; orange |

| 48 | Beam | 4″ x 147″ x 1 5/8″ | Ridg-U-Rak; white |

| 502 | Wire Deck | 42″ x 46″ | Inside WF; 3 channel |

| 144 | Wire Deck | 48″ x 46″ | Double WF; 3 channel |

| 234 | Wire Deck | 60″ x 46″ | Double WF; 3 channel |

| 3 | Building Column Protector | Fits 6″x6″ column | 42″T – 15″ diameter |

| 8 | Building Column Protector | Fits 10″x10″ column | 42″T – 24″ diameter |

| 312 | Row Spacer | 12″ | |

| 2,990 | Gravity Conveyor | 31″; 1.9″ rollers 3″ o.c. | Qty in ft. |

| 5,064 | Slider Belt Conveyor | 31″ | Qty in ft.; Automotion |

| 6,240 | Slider Belt Conveyor | 36″ | Qty in ft.; Automotion |

| 488 | Slider Belt Trash Conveyor | 36″OAW x 12″ sideguards | Qty in ft.; Automotion |

| 1,909 | Photo Eye Accumulation | 31″; 36″ zones | Qty in ft.; Automotion |

| 326 | Belt Driven Live Roller | 31″ | Qty in ft.; Automotion |

| 310 | MDR Roller Accumulation | 31″ | Qty in ft.; Automotion |

| 1,720 | MDR Belt Accumulation | 31″ | Qty in ft.; Automotion |

| 607 | Line Shaft Conveyor | 31″ | Qty in ft.; Automotion |

| 60 | Belt Over Roller Conveyor | 31″ | Qty in ft.; Automotion |

| 740 | MDR Belt/Brake Meter | 31″W x 32″L Sections | Qty in ft.; Automotion |

| 260 | Slider Incline/Decline | 31″W x 20’L | Qty in ft.; Automotion |

| 660 | Slider Incline/Decline | 31″W x 30’L | Qty in ft.; Automotion |

| 720 | Slider Incline/Decline | 31″W x 40’L | Qty in ft.; Automotion |

| 250 | Slider Incline/Decline | 31″W x 50’L | Qty in ft.; Automotion |

| 120 | Slider Incline/Decline | 31″W x 60’L | Qty in ft.; Automotion |

| 70 | Slider Incline/Decline | 31″W x 70’L | Qty in ft.; Automotion |

| 36 | Narrow Belt Sorter | 31″W | Qty in ft.; 4 LH diverts; Automotion |

| 360 | Narrow Belt Sorter | 31″W | Qty in ft.; 10 RH diverts; Automotion |

| 143 | Narrow Belt Sorter | 32 1/2″W | Qty in ft.; bi-directional; Automotion |

| 255 | Narrow Belt Sorter | 33″W | Qty in ft; 5 LH diverts; Automotion |

| 6 | Narrow Belt Sorter | 43″W x 3’L | Qty in ft. |

| 120 | Narrow Belt Sorter | 36″W | Qty in ft.; Automotion |

| 8 | Chute | Tilt Tray Sorter | Qty in units |

| 878 | Buemer Tilt Tray Sorter | 320 trays; 24″W x 32″L (est.) | Qty in lin. ft. |

| 30 | Ball Transfer Table | 31″W x 66″ to 78″W | Qty in units |

| 2 | Spur Curve | 31″ | Qty in units |

| 30 | 90 Degree Roller Curve | 31″ | Qty in units |

| 6 | 90 Degree MDR Curve | 31″ | Qty in units |

| 2 | 90 Degree Belt Curve | 31″ | Qty in units |

| 5 | 90 Degree Skatewheel Curve | 31″ | Qty in units |

| 1 | Merge; 2:1 | 54 1/2″W x 10’L | Qty in units; Automotion |

| 1 | 180 Degree Powered Curve | 31″ | Qty in units |

| 2 | 180 Degree MDR Curve | 31″ | Qty in units |

| 3 | 180 Degree Belted Curve | 31″ | Transnorm |

| 1 | Power S Curve | 31″ | Qty in units |

| 5 | Skatewheel Curve | 31″ | Qty in units |

| 33 | Spring Loaded Lift Gate | 48″ | Qty in units |

| 239 | Hstands | ||

| 1 | Spiral | Gravity Skatewheel | |

| 4 | Spiral | Ambiflex powered | Various heights incline / decline |

| 62,500 | Pick Module A-C | 250′ x 250′ Footprint; Ground plus 2 upper levels | Qty in sq. ft. of footprint; total of 187,500 sq. ft. on all 3 levels; rack-supported module; 32 ea. 36″ pick aisles on ground and second level; 3500 total pick bays each in ground and second levels or 7,000 total; 4 cantilevered shelf levels per bay; third level dance floor; sprinkler and lights; 5 stairways; safety netting |

| 711 | Upright | 46″ x 21’10” x 4″ x 3″ | TD; closed column |

| 77 | Upright | 46″ x 26′ x 4″ x 3″ | TD; closed column |

| 3,920 | Beam | 4″ x 89″ x 1 5/8″ | TD |

| 3,920 | Beam | 5″ x 89″ x 1 5/8″ | TD; cross-aisle |

| 15,680 | Shelf Support | 52″ x 2″ x 2″ | Cantilever |

| 15,680 | Wire Deck | 23″ x 48″ | Tek screwed |

| – | B Deck | 3′ x 20′ | Qty in sq. ft; dimension estimated |

| 125,000 | ResinDek | Qty in sq. ft. | |

| 51,336 | Pick Module D | 184′ x 279′ Footprint; Ground plus 2 upper levels | Qty in sq. ft. of footprint; total of 154,000 sq. ft. on all 3 levels; rack-supported module; 17 ea. 66″ pick aisles per level; 1,134 total pick bays in the 3 level module with approx. 4 shelf levels per bay; sprinkler and lights; 5 stairways; safety netting |

| 322 | Upright | 60″ x 35′ (est.) x 3″ x 3″ | Ridg-U-Rak; 5″ x 6″ FP |

| 77 | Upright | 60″ x 35′ (est.) x 3″ x 3″ | Teardrop |

| 2,376 | Beam | 4″ x 66″ x 1 5/8″ | Cross-aisle; J hook |

| 5,881 | Beam | 4″ x 147″ x 1 5/8″ | Ridg-U-Rak; white |

| 1,232 | Beam | 5″ x 147″ x 1 5/8″ | Ridg-U-Rak; down-aisle; white |

| 1,680 | Beam | 4″ x 147″ x 1 5/8″ | Teardrop |

| (0) | Beam | 6.5″ x 147″ x 1 5/8″ | Teardrop |

| 9,072 | Wire Deck | 60″ x 72″ | Double WF; 4 channel |

| – | B Deck | Qty in sq. ft. | |

| 55,852 | ResinDek | Qty in sq. ft. | |

| 48,945 | Pick Module E | 184′ x 266′ Footprint; Ground plus 2 upper levels | Qty in sq. ft. of footprint; total of 195,780 sq. ft. on all 3 levels; rack-supported module; 17 ea. 66″ pick aisles per level; 1,080 total pick bays in the 3 level module with 4 shelf levels per bay; sprinkler and lights; 4 stairways; safety netting |

| 374 | Upright | 60″ x 35′ (est.) x 3″ x 3″ | Ridg-U-Rak; 5″ x 6″ FP |

| 22 | Upright | 60″ x 35′ (est.) x 3″ x 3″ | Teardrop |

| 2,142 | Beam | 4″ x 66″ x 1 5/8″ | Cross-aisle; J hook |

| 5,289 | Beam | 4″ x 147″ x 1 5/8″ | Ridg-U-Rak; white; 2,730 lbs. cap. |

| 1,120 | Beam | 5″ x 147″ x 1 5/5″ | Ridg-U-Rak; down-aisle; white |

| 1,558 | Beam | 4″ x 147″ x 1 5/8″ | Teardrop; 2,730 lbs. cap. |

| (15) | Beam | 6.5″ x 147″ x 1 5/8″ | Teardrop |

| 8,640 | Wire Deck | 60″ x 72″ | Double WF; 4 channel |

| – | B Deck | Qty in sq. ft. | |

| 53,422 | ResinDek | Qty in sq. ft. | |

| 2,340 | Metal Divider | 12″H x 24″D | Tek screwed |

| 600 | Clear Span Mezzanine | 20′ W x 50′ L | 12′ 6″ clear; bar grate; one stairway |

| 2,625 | Conveyor Support Structure | 8.3’W x 315’L | Qty in sq. ft; 9′ clear; bar grate |

| 3,200 | Conveyor Support Structure | 40’W x 80’L | Qty in sq. ft.; grid only |

| 3,360 | Conveyor Support Structure | 21’W x 80’L | Qty in sq. ft.; bar grate; 2 levels |

| 5,320 | Conveyor Support Structure | 28’W x 190’L | Qty in sq. ft.; ceiling hung |

| 6,666 | Conveyor Support Structure | 22.4′ Wide x 297′ Long | Qty in sq. ft.; approx. 20′ clear |

| 8,320 | Conveyor Support Structure | 40’W x 208’L | Qty in sq. ft; 22’clear; B deck and Resin Dek |

| 9,360 | Conveyor Support Structure | 26’W x 360’L | Approx. 22′ clear; bar grate |

| 58 | Steel Shelving | 18″D x 36″W x 72″H | Qty in sections; Deluxe; 6 shelves per section |

| 1,195 | Steel Shelving | 18″D x 48″W x 75″H | Qty in sections; Deluxe; 5 shelves per section |

| 12 | Steel Shelving | 24″D x 36″W x 72″H | Qty in sections; Deluxe; 5 shelves per section |

| 5 | Safety Gate | 72″W (est.) | |

| 1,332 | Locker | 12″W x 15″D x 11.5″H | Qty in openings; 5 high units; Penco |

| 2 | Air Compressor | ||

| 2,500 | Guide Rail | 3″ x 6″ x 3/8″ | Qty in ft; holes 24″ o.c. |

| 7 | Tote Rolling Shelves | 24″D x 142″L x 74″H | 3 levels |

| 4 | Boom Truck Loader | 36″W x 30’L (contracted) | Best Reach; 24″W belt |

| 4 | Boom Truck Loader | 36″W x 36’L (contracted) | Rapistan; 24″W belt |

| 4 | Extra Batteries | 24v | |

| 2 | Extra Chargers | 24v | |

| 1 | Double Walkie | DW160 | |

| 1 | Golf Cart | just serviced with new battery | |

| 10 | Pack Mule | ||

| 1 | Generator | ||

| 16 | Step Ladder | 3 step 31” to top step | |

| 5 | Step Ladder | 5 step 50” to top | |

| 4 | Step Ladder | 7 step 70” to top | |

| 3 | Step Ladder | 8 step 81” to top | |

| 4 | Step Ladder | 10 step 100” to top |

Frequently asked questions

Do you serve my location?

Conesco serves the entire United States operating from multiple locations with a team across the country.

How quickly can we get started?

It might be quicker than you think! The first step is to give us a call or fill out a form and have us call you. Once we have a good understanding of your unique situation, we typically provide a quote within 5 days and will schedule a time with you to have one of our team members come visit your site.

How long will the used equipment removal process take?

We get that question all the time! It depends on many factors such as:

- when will the inventory be cleared off the shelf levels?

- will the warehouse be shut down or,

- will it still be operating?

- How much material is there?

- Are the uprights bolted down to the ground?

- What is your timeline?

- When do you need the material out of the facility by?

Best practice is to give yourself multiple months of time in planning so that way you provide a buffer for your project to finish according to a timeline. Getting a full count of the materials and good pictures is a great way to start the process of evaluating the decommission of your warehouse.

Will you buy and remove everything from our warehouse?

Our specialty is in used material handling equipment, especially pallet racking (uprights, beams, wiredecks, pallet supports, row spacers), pallet rack accessories (like end aisle guards, guide rail, guard rail, netting), conveyor systems, mezzanines, and pick modules. Other warehouse material handling equipment we can buy/ remove from your warehouse also include:

- flexible conveyors

- balers

- shrink wraps

- industrial scales, or

- lifts

Sometimes material is in bad shape or is a very uncommon size or outdated brand. In some of these cases we do not purchase the materials, however we still can provide you with our teardown services to remove the materials from your warehouse. We encourage everyone to reach out so we can better understand what is in your warehouse and what your intentions are. Once we have a good understanding, we are happy to provide you with our recommendations, even if that means not using us.

Will you clean up after you have finished with the dismantle and equipment removal?

Will you leave holes in the floor or walls?

We are still operating. Can you work around us?

Working with Conesco

From large scale, multi-faceted projects to cost-savings on materials, we support a diverse customer base with:

Experience

More than 37 years in facility decommission / liquidation experience

Consultation

Reduce Risk

Experienced teams who operate safely and quickly

Maximize Value

Receive a top dollar bid that often will exceed fair market value

Savings

Remove the burden of handling multiple vendors and projects by working with Conesco

Confidence

Have confidence you are working with an experience partner who is customer & solutions oriented