Maximize Value

Amplify Space

Improve Efficiency

Save Time & Money

Industrial Warehouses One Stop Shop

Leverage a National, Diverse Industry Network

Move Your Project Fast, Like a Pro

CONESCO COMBINES 400+ YEARS OF INDUSTRY EXPERIENCE:

New and Used Material Handling Equipment Sales

Warehouse Liquidations

Facility Decommissions, Transitions, & Moves

Services (Installs, Teardowns, Decommissions, Transitions)

Logistics (Freight + Coordination)

Avoid frustrating, over budget projects

Avoid struggling to find the right people with the right expertise, network, work-ethic, and responsiveness

Avoid project design or implementation risk which may result in accidents

Avoid being saddled with equipment that doesn’t produce the efficiency or productivity desired

Avoid failed projects due to a lack of internal resources or know-how

Avoid paying too much for equipment or labor

The Conesco Storage Systems process

How to Consult with Conesco

Request a Free Consult to Discuss Your Needs

Identify Needs, Timeline, &, Priorities

Receive a Custom Proposal(s)

Have confidence in your project, timelines, budget, and operation.

Industry Profiles

From large scale, multi-faceted projects to cost-savings on materials, we support a diverse customer base

3PL

eCOMMERCE

E-commerce fulfillment centers rely on Conesco fulfilling their material handling system needs to maximize storage capacity while efficiently processing and shipping orders to customers.

WAREHOUSING

Distribution centers maximize their material handling equipment by partnering with Conesco to amplify their space and optimize the flow of goods through their facilities.

FOOD & BEVERAGE

Food and beverage warehouses work with Conesco to maximize their material handling equipment and implement equipment like pick modules and automated picking and packing systems to increase accuracy and efficiency.

COLD STORAGE

Cold storage warehouses optimize their material handling equipment by using specialized technologies like automation technologies like AS/RS and robotic picking systems to optimize the flow of goods & reduce damage/ spoilage

MANUFACTURING

Manufacturers partner with Conesco to integrate material handling equipment like automated systems such as conveyor belts, robotic arms, and pick-and-place machines to move materials and products throughout the facility.

Have Confidence with Conesco

Conesco provides nationwide experts with experience & work-ethic.

We leverage a global network of industry partners, for you.

We offer support for your entire material handling needs.

We are your trusted business advisor. We think about your projects as you do.

We offer a wide variety of new and used options for pallet racking, conveyance, mezzanines, pick modules, and specialty equipment.

We are a full-service partner. We can help with planning, design, budgeting, evaluation, recommendations, best practices, and execution of your warehouse projects.

We maximize your investment and the full utilization of your facilities.

Material Handling Equipment

Pallet Racking

Uprights, beams, wiredecks, pallet supports, row spacers

Conveyor

Mezzanines

Find a mezzanine the fits your load capacity, size, and design features to meet your operational needs

Cantilever Rack

Vertical columns (‘towers’), horizontal bases, arms, bracing, and hardware

Pick Modules

Mezzanines/ platforms, conveyor, racking/ shelving, stairs, safety equipment (ie guardrails)

Lifts & Machines

Forklifts, reach trucks, AS/RS, pallet jacks, balers, scales, wrapping machines, truck loaders, dock ramps, +more

Wire Decking

Double Water Fall, Flared, Reverse Water Fall, Drop-in, Flush

Shelving

Industrial Steel Shelving, Boltless, Steel, +more

COMMITMENT & TRADITION

Focusing on our customer’s needs and bringing them maximum value, since 1986.

“We founded Conesco to repurpose pre-owned pallet racking & extend great cost-savings to customers…

Today, we provide new & used material while offering turn-key services to support our customers in all stages of their material handling equipment needs.”

– Ted Hodges, CEO & Founder

Conesco buys, sells, and provides labor

Industrial warehousing SERVICES

New & Used Material Sales

WAREHOUSE LIQUIDATIONS

LABOR SERVICES

LOGISTICS COORDINATION

WAREHOUSE PLANS & STRATEGY

ENGINEERING & PERMITTING

PROJECT MANAGEMENT

FACILITY/ MATERIAL CONSULTING

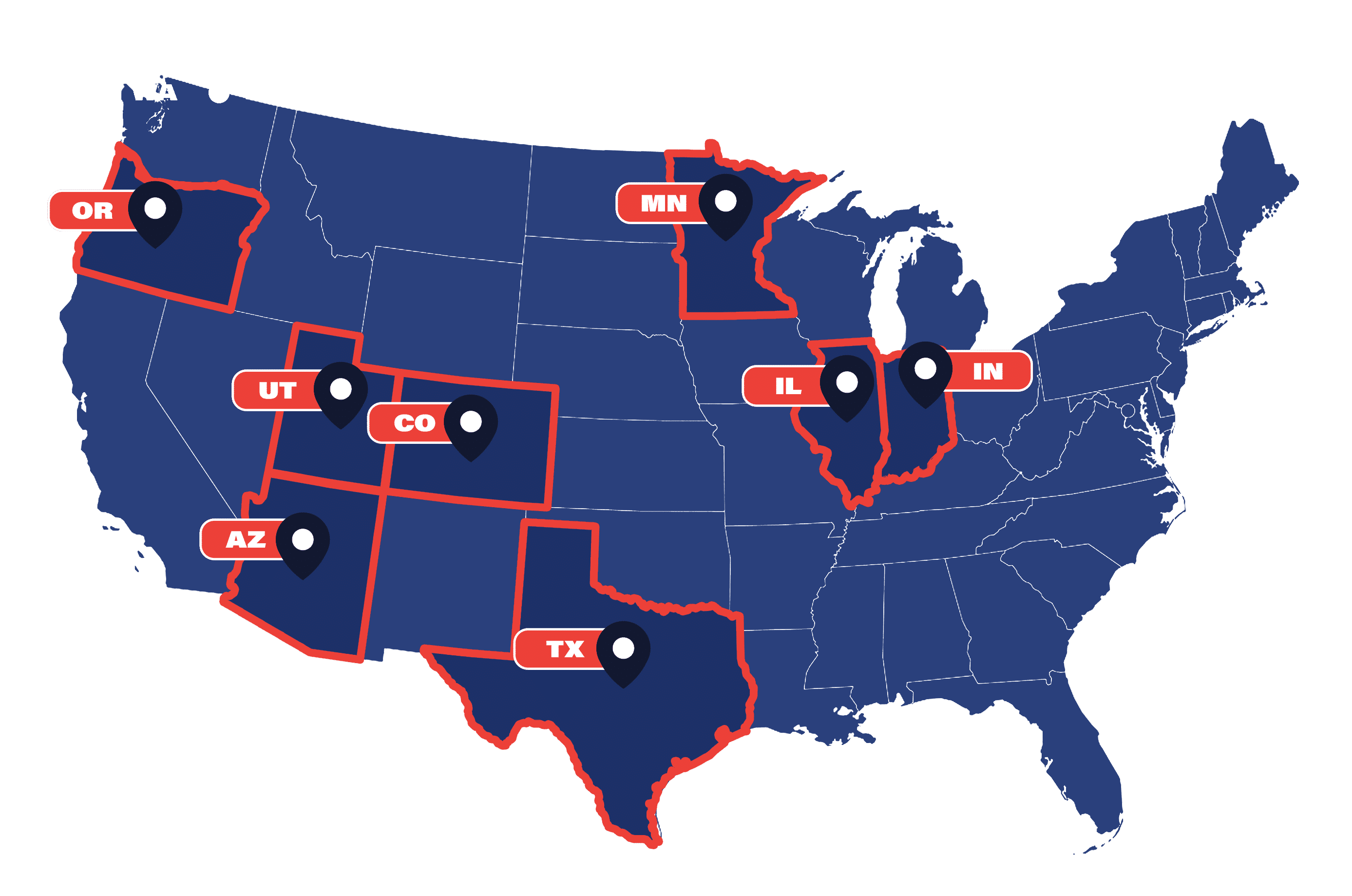

NATIONWIDE TEAM

Two Physical Locations with Pallet Racking + More MHE. Conesco’s Team is across the USA ready to deploy for your next project.

We saved over $1M in our initial budget by choosing to work with Conesco and asking them to source the racking material we needed pre-owned. Conesco sourced thousands of pallet positions for us. We were able to allocate the savings into our inventory and operations expenses. We did not realize that we would save over 50% by choosing used equipment over new. Thank you, Conesco!

– National 3PL Company

Want a top dollar offer for your

pallet racking | Pick Module | Conveyor | Mezzanine…?

Warehouse Liquidations

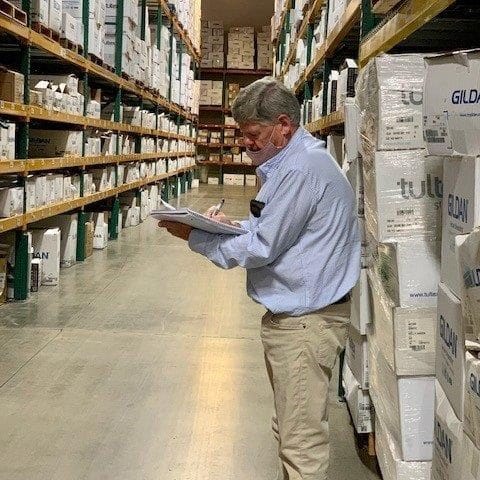

Conesco’s team of experts has extensive knowledge of the equipment and machinery used in warehouses, allowing them to accurately assess the value of assets and provide top dollar, fair market bids to businesses.

Conesco also offers comprehensive equipment removal and decommissioning services, ensuring that businesses quickly and safely remove their assets. By working with Conesco, businesses free up valuable space and can receive capital bac to reinvest in their core operations.

By partnering with Conesco for their warehouse liquidation needs, businesses save time and money while benefiting from the expertise and experience of a trusted industry leader.

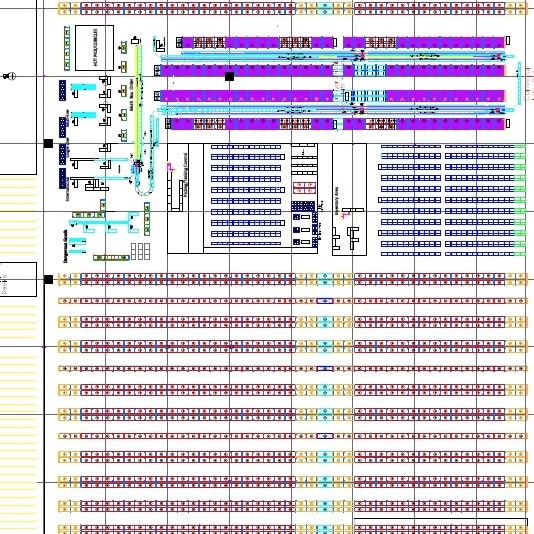

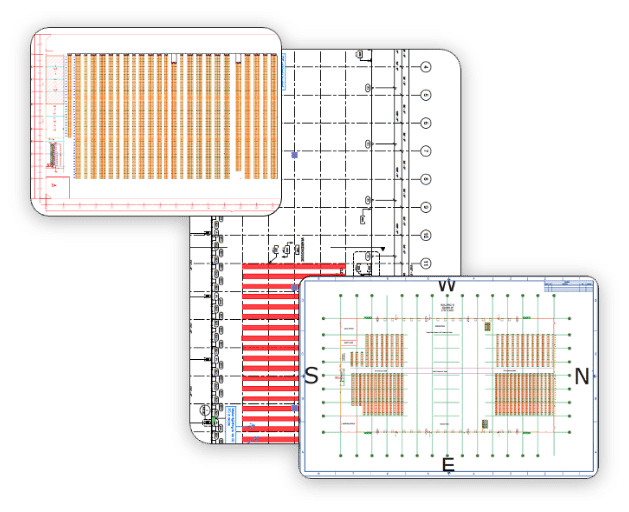

Warehouse Planning

DESIGN TO PROJECT MANAGEMENT

DRAWINGS | ENGINEERING | PERMITTING | INSTALLING

EXPERTS IN MATERIAL HANDLING SOLUTIONS

New & Used Industrial Pallet Rack

We saved over $1M in our initial budget by choosing to work with Conesco and asking them to source the racking material we needed pre-owned. Conesco sourced thousands of pallet positions for us. We were able to allocate the savings into our inventory and operations expenses. We did not realize that we would save over 50% by choosing used equipment over new. Thank you, Conesco!

– National 3PL Company

Do you need help with material handling equipment?