Picking the wrong pallet rack is an expensive mistake. It affects how much weight you can store, how often you’re dealing with damage, and how much you pay upfront versus over time. And when the wrong system is already installed, fixing it means downtime, labor, and unplanned spend.

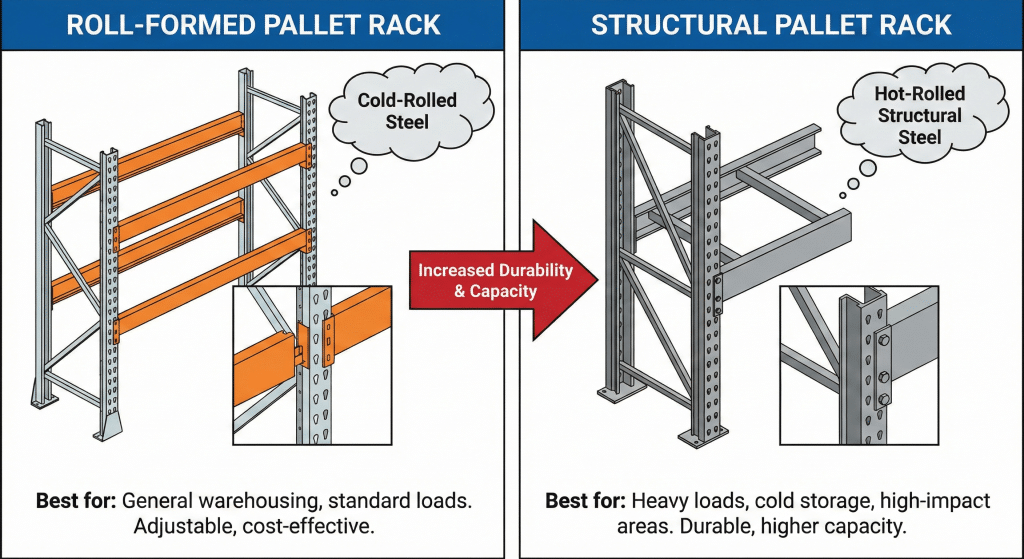

The two most common rack types warehouses use are roll formed pallet rack and structural pallet rack. They look similar from a distance. Under the hood, they’re built differently, connect differently, and perform very differently depending on what you’re asking them to do.

Conesco Storage Systems works with both. This guide breaks down how each system is built, where each one wins, and how to figure out which one makes sense for your operation.

What Is Roll Formed Pallet Racking?

Roll formed rack is made from cold-rolled sheet steel. Manufacturers run flat steel coils through a series of rollers that bend and shape the metal into uprights and beams. The punch pattern on the uprights, most commonly a teardrop-style slot, is what lets beams connect without tools in most configurations.

It’s the most common rack system in use today. The uprights are lighter, easier to handle, and faster to install. That makes it a natural fit for operations that need to get up and running quickly or that expect to reconfigure their layout as inventory needs change.

Cost is a real advantage. Roll formed rack typically costs less per unit than structural, and because it’s widely manufactured, replacement parts are easy to source. Many warehouses Conesco services already run roll formed systems, which means adding bays or expanding a section is often straightforward.

What Is Structural Pallet Racking?

Structural rack is built from hot-rolled steel, typically formed into C-channels or I-beams. The steel is thicker and heavier. Beams bolt directly through pre-punched holes in the uprights instead of hooking in.

The result is a rack system that is more rigid, more impact resistant, and capable of handling significantly higher loads. It’s the standard choice in high-throughput distribution centers, food and beverage facilities, building materials storage, and any environment where forklifts are moving fast and frequently.

Structural rack is not the most flexible system. Once it’s up, reconfiguring it takes more time and labor. But in the environments it’s built for, that tradeoff is worth it.

How They’re Made, and Why It Matters

The strength differences between roll formed and structural rack start in how they’re manufactured.

Roll formed rack gets its strength from the bends in the steel. Flat steel has relatively little structural rigidity on its own. When it’s cold-rolled into channels and angles, those bends add stiffness and load capacity. The more bends engineered into the profile, the stronger the component. This is effective for standard warehouse loads, but it does mean the strength is tied to the shape of the formed profile.

Structural rack starts with hot-rolled steel that is already at its maximum strength once it cools into its final channel shape. You cannot bend a structural component after forming without compromising its integrity. That’s actually the point. The steel is dense, rigid, and designed to stay that way under repeated impact and load stress.

The practical takeaway: roll formed components can flex slightly under load and are more susceptible to bending from forklift impact. Structural components resist that deformation far better.

Beam-to-Frame Connections: Rivets vs. Bolts

How the beams connect to the uprights is one of the clearest practical differences between the two systems.

Roll formed connections use a rivet or hook-style mechanism. Beams drop into teardrop-shaped slots on the upright and are secured with safety clips. No bolts, minimal tools, fast installation. This is what makes roll formed systems so easy to adjust. You can change beam heights or add levels in minutes.

Structural connections use bolts. Beams attach through pre-drilled holes in the upright, creating a rigid frame. This takes longer to install and adjust. The tradeoff is a connection that won’t loosen over time, won’t be knocked out of position by forklift contact, and adds overall frame rigidity.

In environments with heavy forklift traffic or high cycle counts, the bolted connection on structural rack is a meaningful safety and durability advantage.

Side-by-Side Comparison

Here’s how the two systems stack up across the factors that matter most.

| Factor | Roll Formed Rack | Structural Rack |

| Manufacturing | Cold-rolled sheet steel formed and punched | Hot-rolled steel channels cut and drilled |

| Connection | Rivet/teardrop, clip-secured beams | Bolted beam-to-upright connections |

| Capacity | Lower load capacity per beam pair | Higher upright and beam capacities for heavy loads |

| Impact Resistance | More susceptible to forklift damage | More resistant to abuse and collisions |

| Flexibility | Very easy to reconfigure or relocate | More permanent, harder to reconfigure quickly |

| Cost | Lower material and installation cost | Higher upfront cost but longer service life |

Real Load Capacity Numbers: What to Expect

Talking about capacity in relative terms only gets you so far. Here’s what actual systems look like in practice.

Standard Roll Formed System

- 42-inch deep frame, 3-inch step beam, 96-inch length

- Beam capacity: 4,500 to 6,000 lbs per beam pair

- Upright capacity: 18,000 to 24,000 lbs per frame depending on height and bracing

- Steel thickness: 14 to 16 gauge uprights

- Common use: general warehousing, consumer goods, e-commerce fulfillment

Heavy Roll Formed Configuration

- 48-inch deep frame, 4-inch structural-style roll formed beam, 108-inch length

- Beam capacity: 7,000 to 8,500 lbs per beam pair

- Upright capacity: 25,000 to 30,000 lbs per frame

- Upright gauge: 12 to 14 gauge

- Common use: loads approaching structural territory where layout flexibility is still needed

Structural Rack System

- 48-inch deep structural frame, 5-inch structural C-channel beam, 108-inch length

- Beam capacity: 9,000 to 15,000 lbs per beam pair

- Upright capacity: 35,000 to 50,000 lbs per frame depending on column size

- Steel: hot-rolled structural channel, typically 3-inch to 5-inch column

- Common use: food and beverage, building materials, high-bay distribution, drive-in rack systems

Actual capacity depends on beam length, column size, steel grade, and seismic requirements. Always verify stamped load charts before configuring or loading any rack system.

Cost, Installation, and Total Lifecycle Value

Roll formed rack wins on upfront cost. Lower material cost, faster installation, and widely available replacement parts all contribute to a smaller initial investment. For operations with lighter loads, careful forklift practices, and predictable layouts, roll formed is often the right economic choice.

Structural rack costs more to buy and more to install. But in the right environment, that cost spreads over a much longer service life. Fewer damaged uprights, fewer repairs, less downtime. In facilities where forklift damage to roll formed rack is a recurring problem, the math on structural often works out in the long run.

Conesco offers both new and quality used rack, which changes the cost equation significantly. Before choosing new or used equipment, review our used pallet rack buying guide to compare condition grading, capacity verification, and cost savings. Buying used structural rack through Conesco can get you heavy-duty performance at roll formed prices.

Safety, Codes, and Environmental Fit

Both rack types must meet load capacity requirements and carry proper engineering documentation. Capacity labels, load calculations, and certified designs are non-negotiable regardless of which system you choose.

Both roll formed and structural pallet rack systems should be designed in accordance with ANSI MH16.1 (2023 edition: Specification for the Design, Testing, and Utilization of Industrial Steel Storage Racks), which governs structural design requirements, load application standards, seismic design criteria, and testing methods. Note that ANSI MH16.1 covers selective pallet racks, movable-shelf racks, and rack-supported systems, but does not cover drive-in or drive-through rack configurations. Those fall under the separate ANSI MH16.4 standard.

The Rack Manufacturers Institute (RMI) recommends documented load capacities, routine inspections, and prompt repair of damaged uprights to maintain compliance and safety. Their published practices cover capacity labeling, inspection criteria, and damage assessment standards that apply to both rack types.

OSHA 29 CFR 1910.176(b) requires stored materials to be stable and secured against sliding or collapse. That standard applies regardless of rack type and reinforces the importance of proper load rating verification and upright inspection.

Where the systems differ is in environmental performance. Structural rack is the better choice in seismic zones where code requirements are more demanding. It handles the repeated physical stress in cold storage and freezer environments better than roll formed. In facilities with high-traffic aisles and frequent forklift movement, structural’s impact resistance directly reduces safety risk.

Roll formed rack performs well in controlled environments with lighter traffic and trained operators. If your team is disciplined about forklift speed and aisle clearance, roll formed can serve you for years without issue.

Routine pallet rack inspection services help identify column damage, missing anchors, and overloaded beam pairs before they become safety issues. Conesco can support layout planning, permitting, and rack inspections as part of a turnkey project.

When Roll Formed Is the Right Choice

Roll formed rack makes sense when your application doesn’t demand the added cost or rigidity of structural. Here are the scenarios where it performs best:

- Standard to medium pallet loads that don’t push the limits of roll formed beam capacities

- E-commerce fulfillment and general warehousing where layouts change as SKU mixes shift

- Operations with careful forklift practices and lower day-to-day impact risk

- Fast-growing businesses that need to expand or reconfigure storage without major labor investment

- Budget-conscious projects where cost per bay matters and load requirements are within roll formed’s range

Conesco can source new or used roll formed components to expand an existing system, match current rack heights, or build out new sections in a way that keeps costs down.

When Structural Is the Right Choice

Structural rack is the correct answer when load demands are high, forklift activity is heavy, or the environment is harsh. Specific scenarios:

- Heavy pallets in industries like food and beverage, building materials, and manufacturing

- High-bay storage where load capacity per upright matters significantly

- Drive-in, drive-through, or push-back rack systems where forklifts enter the rack structure and frame rigidity matters (note: these systems are governed by ANSI MH16.4, not ANSI MH16.1)

- 24/7 distribution centers with continuous forklift traffic across all shifts

- Facilities with recurring upright damage where roll formed rack is being replaced repeatedly

- Cold storage and freezer environments where structural integrity under temperature stress is a factor

Conesco designs structural systems from the ground up and can integrate them into larger material handling solutions including conveyors, mezzanines, and pick modules.

Hybrid Strategies: Using Both in the Same Facility

Not every facility falls cleanly into one category. A common and cost-effective approach is using structural rack in high-impact zones, like the main forklift aisles or heavy product pick areas, and roll formed in lower-traffic sections.

This lets you allocate budget where the risk is highest while keeping costs down in areas that don’t need structural’s added strength. It requires some upfront planning to make sure the layout makes sense, but the result is a system that performs well without overbuying on every bay.

Early warehouse layout planning services can help you model load distribution, aisle width, and rack type placement before installation. If you’re planning for future automation, higher storage density, or a building expansion, the rack type you choose today affects your options later. Structural rack integrates more cleanly into automated systems and high-bay configurations.

Conesco’s team can help you think through long-term facility planning, including teardown, relocation, and liquidation when needs change.

How Conesco Helps You Make the Right Call

The roll formed vs. structural decision depends on your specific load requirements, traffic patterns, budget, and growth plans. Getting it wrong costs money in repairs, downtime, or a premature system replacement.

Conesco’s process starts with a real evaluation, not a catalog. That means reviewing your current rack, assessing damage, understanding your traffic patterns, and looking at your growth plans before recommending a system. The goal is to match the right rack to what you’re actually doing.

Services include buying used rack, selling new and used systems, turnkey installation, and safe dismantling and liquidation of existing equipment. If you’re upgrading from roll formed to structural, rack liquidation and relocation services can offset part of the new system cost. Whether you’re outfitting a new facility or upgrading an existing one, Conesco can handle the full project.

Ready to move forward?

- Schedule a rack assessment with Conesco

- Request a roll formed vs. structural quote for your project

- Send your current layout for a free review

Frequently Asked Questions

What is the main difference between roll formed and structural pallet rack?

Roll formed rack is made from cold-rolled sheet steel bent into shape, with hook-style beam connections that clip into teardrop upright slots. Structural rack is built from hot-rolled steel channels and uses bolted beam-to-upright connections. Structural is heavier, more rigid, and better suited for high-load or high-impact environments.

Which pallet rack type is stronger?

Structural pallet rack is stronger. It starts with thicker hot-rolled steel that reaches maximum strength in its final form. Roll formed rack gains strength from bends in the steel but is more susceptible to deformation under impact or extreme load conditions.

Is roll formed pallet rack safe for heavy loads?

Roll formed rack is safe when used within its rated capacity. For very heavy pallets or high-bay storage with demanding load requirements, structural rack is typically the better fit. Always verify load ratings with an engineer before installing any rack system.

Why does structural pallet rack cost more?

Structural rack uses more steel, thicker profiles, and requires more labor to install due to bolted connections. The higher upfront cost is offset over time by lower damage rates, longer service life, and reduced maintenance in demanding environments.

Can you mix roll formed and structural pallet rack in the same warehouse?

Yes. A hybrid approach is common and cost-effective. Many facilities use structural rack in high-traffic or heavy-load aisles and roll formed in lower-impact areas. The key is planning the layout so each rack type is matched to the right application.

What industries use structural pallet rack most often?

Structural rack is common in food and beverage, building materials, manufacturing, and large-scale distribution. Any industry with heavy pallet weights, 24/7 operations, or frequent forklift activity is a strong candidate for structural systems.

How are pallet rack beams connected to uprights?

Roll formed rack uses a rivet or hook-style connection where beams drop into teardrop slots on the upright and are secured with safety clips. Structural rack uses bolted connections, where beams bolt directly through holes in the upright to create a rigid frame.

Which pallet rack type is easier to install and reconfigure?

Roll formed rack installs faster and is much easier to reconfigure. Beam heights can be adjusted quickly without special tools. Structural rack takes longer to install due to bolted connections but offers superior rigidity once in place.

What is the load capacity difference between roll formed and structural pallet rack?

Load capacity varies by specific product and configuration, but structural rack generally supports higher per-beam and per-upright capacities than comparable roll formed systems. Always check the manufacturer’s load ratings and get an engineer to verify your layout.

How do I decide which pallet rack type is right for my warehouse?

Start with your load requirements, forklift traffic patterns, budget, and whether your layout will change frequently. Roll formed fits most general warehousing applications. Structural is the right call for heavy loads, harsh environments, or facilities with recurring damage issues. Conesco can evaluate your specific situation and recommend the right system.

Key Takeaways

- Roll formed rack is more economical, easier to reconfigure, and well-suited for standard warehouse applications

- Structural rack is heavier, more rigid, and the right choice for heavy loads, harsh environments, and high-impact forklift zones

- Manufacturing method determines performance ceiling, cold-rolled sheet steel for roll formed, hot-rolled channel steel for structural

- Bolted connections on structural rack add durability and resist loosening over time, rivet connections on roll formed prioritize speed and flexibility

- A hybrid approach can balance cost and durability by placing each system where it performs best

- Total cost of ownership matters more than upfront price, buying quality used structural rack through Conesco can close the cost gap significantly

- Get a professional assessment before buying, the right rack depends on your specific loads, traffic, and layout