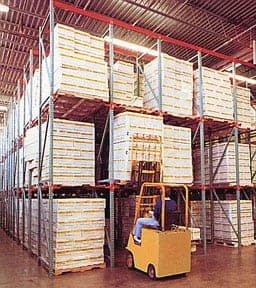

It may look like chaos to an outsider, but a warehouse is a carefully orchestrated dance of receiving new materials, sending materials out, and rotating orders. A warehouse will not be successful unless they are organized and have the right type of equipment to get the job done. A large part of a warehouse’s operation and efficiency comes from the use of proper warehouse pallets and racking systems. If you’re thinking about getting into the warehouse or storage system, you must know about proper pallet racking to help your plans succeed. We have 3 ways to use pallet racking in a warehouse to share with you. Let’s review some of the different forms of pallet racking to give you an idea of what you’ll be working with.

Drive-In and Drive-Thru Pallet Racking

As the name implies drive-in and drive-thru pallet racking systems are designed for forklift or warehouse personnel to drive directly into a racking unit or drive through a racking unit. This setup is used for efficiency of movement, with drive-in pallet racking being useful for last in, first out (LIFO) storage methods, and drive-thru being an option for both LIFO and first-in, first-out (FIFO) warehouse storage systems.

Push-back Pallet Racking

Warehouses uses push back pallet racking to organize the warehouse by depth as opposed to width. This system does reduce aisle space but can greatly increase the number of materials or product your warehouse can hold and store. Push-back pallet racking is most often seen in a LIFO storage method.

Pallet Flow Systems

Pallet flow systems are one of the most popular types of pallet racking due to their efficiency and are used when you need high-density storage. You can use pallet flow systems in both LIFO and FIFO methods of storage, depending on if you want to load from the back and unload in the front, or load and unload from the front of the rack. Pallet flow systems may also be referred to as gravity flow racks.

Every warehouse has its own unique needs and uses for pallet racking, but all must use pallet racking to stay efficient and organized. If you need to know what type of pallet racking would work for your current or planned warehouse or storage facility, speak with a storage solution systems expert or representative to get things rolling.

Are you looking to buy and sell warehouse equipment? Get your questions answered here.

[ultimate-faqs]