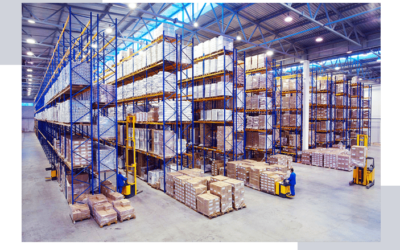

Sell used pallet racks in Denver, CO

Relocating or shutting down a warehouse requires that you sell used pallet racks in Denver, CO. At CONESCO, we have been buying and selling used pallet racks since 1986. We know used pallet racks need to be sold in a way that is quick, safe, and for the best dollar return in Denver for your company. While you might have other used warehouse equipment, selling the used pallet racks are one of the most important parts of the warehouse shutdown process. Get the information you need to make the right decision about this important responsibility. Contact us now to learn more about what it takes to sell warehouse used pallet racks in large quantities.

Sell used pallet racks for the best price in Denver, CO

Shutting down a warehouse or distribution center in Denver can be costly–when it’s done the wrong way. Here are a few things that can make the process more expensive:

- Lack of professionalism

- Lack of experience

- Doing it wrong

- Accidents

- Not meeting deadlines

Making the wrong decision about your used pallet rack removal can be costly. Not only will we offer you a fair price, you will get the added value of our professionalism and experience.

Sell used pallet racks quickly

Not only does lack of experience, doing it wrong, and accidents cause a warehouse teardown to cost more, these things can also really slow the process down! Our team at CONESCO has been quoting, planning, and executing the removal of used pallet racks in Denver since 1986. Needless to say, we do this all the time!

Contact us to learn about our efficient method of used pallet racks removal. Our thorough approach to planning keeps us on schedule.

What to expect when selling used pallet racks

Step 1: Let’s talk! We want to know about your unique warehouse or distribution center situation. Are you liquidating? Downsizing? Relocating? We have lots of questions and we’re sure you do, too.

Step 2: Get a custom and detailed quote within 5 days.

Step 3: We get to work! We execute your custom plan based upon a specific timeline.

Frequently asked questions about selling used warehouse equipment

Here are some of our most frequently asked questions:

Do you serve my location?

CONESCO serves the entire United States from multiple locations.

How quickly can we get started?

It might be quicker than you think! The first step is to give us a call or have us call you. Once we have a good understanding of your unique situation, we typically provide a quote within 5 days and will schedule a time with you to have one of our team members come visit your site.

How long will the used equipment removal process take?

We get that question all the time! It depends on many factors such as:

- will the warehouse be shut down or,

- will it still be operating?

- How much material is there?

- Are the uprights bolted down to the ground?

Best practice is to give yourself multiple months of time in planning so that way you provide a buffer for your project to finish according to a timeline. Getting a full count of the materials and good pictures is a great way to start the process of evaluating the decommission of your warehouse.

Will you buy and remove everything from our warehouse?

Our specialty is in used pallet racks (uprights, beams, wiredecks, pallet supports), pallet rack accessories (like guide/ guard rail, netting), conveyor systems, mezzanines, and pick modules. If your warehouse also includes different material like

- balers

- shrink wraps or

- lifts,

then we can buy/ remove those as well.

Sometimes material is in bad shape or is a very uncommon size or outdated brand. In some of these cases we do not purchase the materials, however we still can provide you with our teardown services to remove the materials from your warehouse. We encourage everyone to reach out so we can better understand what is in your warehouse and what your intentions are. Once we have a good understanding, we are happy to provide you with our recommendations, even if that means not using us.

Will you clean up after you have finished with the shelving and equipment removal?

Absolutely! Removing used warehouse equipment is a messy job. All debris will be properly disposed of and the floors swept.

Will you leave holes in the floor or walls?

No. Removing floor anchors does create holes but we take responsibility for grinding them down to be flush with the cement or fill them with cement epoxy.

We are still operating. Can you work around us?

Yes! There are a few things that will need to happen in order to ensure everyone’s safety and some other items need communicated like an agreed upon timeline. It’s true, an operating warehouse will sometimes slow down a teardown project. But, we understand it’s necessary to avoid disruption of your business during the warehouse shelving and equipment removal process.

We are the used pallet rack removal professionals in Denver, CO

Rely on our combined experience and connections to be at your disposal. Material handling equipment, warehouse machines, and supplies require precise knowledge and training to properly maintain and relocate. We are equipped to tear down large square footage warehouses. From pallet racks to lifts and jacks, CONESCO Storage Systems has experience with material handling equipment of all shapes and sizes.

MATERIAL HANDLING SOLUTIONS EXPERTS

NEW & USED INDUSTRIAL PALLET RACK

“Conesco gave us the top dollar cash offer for our standing pallet rack. They also provided the crew to tear it down and get the material out of our building within the tight time-frame that we had to be out. Their team was very helpful throughout the process. We recommend working with them.

~ National Beverage Distribution Company

TALK WITH AN EXPERT. CONTACT US.

Conesco can help. Complete our contact form or call us directly at: (303) 690-9591.

MORE MATERIAL HANDLING RESOURCES

The Complete Guide to Warehouse Planning

Planning or remodeling a warehouse takes a lot of forethought to make product fulfillment most effective and efficient. However, this preparation is...

Buy used warehouse equipment in Seattle, WA

Looking to buy used warehouse equipment in Seattle, WA? You are in the right place. CONESCO has a complete catalog of high quality used warehouse...

Warehouse shelving removal service

Relocating or shutting down a warehouse requires that you sell and remove your warehouse shelving. At CONESCO, we have been buying, tearing down,...